Automating Hydrogen Production

Hydrogen, the emerging clean energy source, will play a key role in the long-term sustainability of energy-intensive manufacturing, processing, and transportation industries. Regardless of the source of hydrogen, whether natural gas or H2O, automation is essential for efficient hydrogen production, storage, and transportation.

Thomas Bertsch, Head of Process Industries in North America at Festo, provides insights into recent developments at Festo for automating hydrogen production.

Question 1: Thomas, please tell us a little about yourself and your focus on automating all aspects of hydrogen production.

Thomas: I’ve spent the last 15 years focused on business development in various positions within the process industries, which include Festo’s activities in hydrogen, chemical processing, oil and gas, and petrochemicals. During those 15 years, I’ve seen nothing that approaches hydrogen’s potential as a clean and abundant energy source.

Festo has invested significant resources in hydrogen automation solutions. Our automation shortens a hydrogen project’s time to market, lowers installation and component costs, and ensures safety. Festo’s modular approach to automating hydrogen production enables efficient scaling up from pilot installations to production facilities. We ensure component availability, competitive price, and significant application and tech support.

Question 2: It is simply not workable to build a Distributed Control System (DCS) at every point of hydrogen generation. The hydrogen industry has responded by developing modular hydrogen generation skids based on the steam methane reforming process and others on electrolysis. What is Festo doing in terms of skid automation?

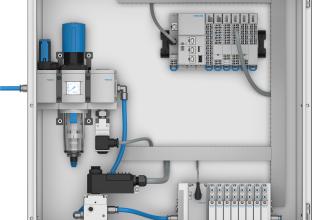

Thomas: Modularity drives costs down and increases flexibility because production output at each site is scaled by adding the number of skids required. Festo’s VTUG-EX is the world’s first fieldbus enabled valve manifold certified to operate in HazLoc Class 1 Division 2 control panels. Having a control panel with this rating on the skid reduces the modular unit’s footprint.

The Festo VTUG is the world’s first valve manifold with fieldbus connectivity for Class 1 Div. 2 applications.

Using a valve manifold rather than running two wires to every pilot valve decreases the size of the control panel, as there are fewer I/O cards. The manifold makes installation and maintenance faster and easier. And the VTUG-EX has IECEX Zone 2/22 certification, creating a global solution for hazardous locations.

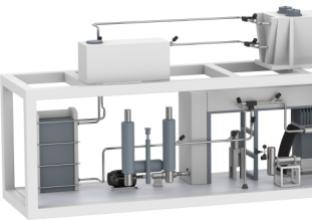

This model of a hydrogen production skid features the control panel, lower right, which meets Class 1 Div. 2 requirements and can be within the hazardous zone.

Control panels are costly to design, specify, and build. Festo Customer Solutions (Festo North America’s fabrication, assembly, and engineering services in Mason, Ohio) manages the entire control panel acquisition process for skids and DCSs. By utilizing one universal part number and one contact person, Festo customers can reduce purchasing costs by as much as 50%, while enhancing process reliability and boosting productivity.

Question 3: Hydrogen is often transported from its point of generation to a hub or point of use. Compression, filling, and dispensing from over-the-road trailers must be monitored and controlled. Does Festo have transportation solutions?

Thomas: Festo worked with GP Joule, an integrated energy supplier, on a hydrogen transportation trailer that features the HY.Runner intelligent trailer control system for hydrogen. This control system is housed in the lower frame area of the chassis, where space is at a premium. To meet SIL 3 safety standards, the control system features a VTUG valve manifold with Festo VOFC solenoid valves. By monitoring and controlling all operating conditions, safety is increased and integration into the safety concepts of filling and extraction points is simplified.

Question 4: Would you agree that safety seems to run through most things connected to hydrogen production?

Thomas: Safety is paramount because hydrogen is highly explosive. Festo has, for example, developed a control system that provides a cost-effective safety circuit up to SIL 3. The system comprises a manifold, proportional control valves, and a solenoid valve to evacuate the air in a safety shutdown.

Festo offers assembled and tested actuator units, whether single or double-acting, that are used in Safety Integrated Systems. These units feature a SIL certified individual valve mounted on the actuator and controlled directly by the safety PLC.

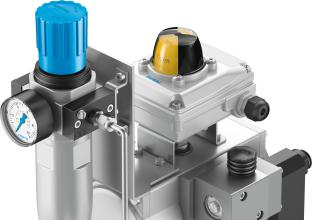

An example of a safety-related actuator unit. The certified valve is mounted directly on the actuator as a NAMUR style valve.

Festo has designed a simple, modular, and cost-effective control panel featuring a valve manifold for basic operation mode and a single solenoid valve for safety shutdown. A certified individual valve is controlled directly by the safety PLC and switches off safely. Certified valves can be used up to SIL3 level.

A control panel with solenoid shutdown valve, bottom left

Everyone who has dealt with designing safety knows that safety loops are challenging. While traditional architecture works, Festo has solutions that are new and more cost-effective process automation alternatives to circuits used in the past.

Question 5: How does Festo improve hydrogen-based DCS production?

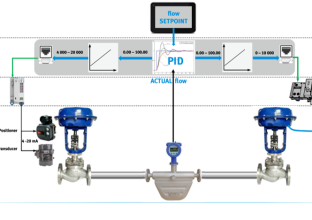

Thomas: In the typical DCS-based automation system, large control panels with PLCs and many I/O cards are housed outside of the hazardous hydrogen location zone. Each I/O card in the typical architecture is connected via individual wire to a field device or pneumatic solenoid valve, with each valve actuated by compressed air. For controlled valves requiring a positioner, there must be two I/O cards running wires to each valve – one wire for the setpoint and another wire for feedback. The individually attached wires and I/O cards result in a high cost for materials, installation, software licenses, and maintenance, as well as a large footprint for the control panel.

Festo offers a better way in terms of cost, materials, installation, and maintenance – eliminate the valve positioner in favor of a valve manifold connected via pneumatic tubing to a proportional control valve. Festo application engineers estimate that proportional control offers a 50% cost advantage over positioners because I/O cards, wires, and other hardware are eliminated, making control panels smaller and less complex. There would also be higher uptime through simpler maintenance and troubleshooting.

On the left, wires, positioners, and transducers are hallmarks of position control. On the right, the valve manifold controls the valve through a single pneumatic connection.

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For more than 50 years in the U.S., Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment. Through advanced technical and industrial education, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies.