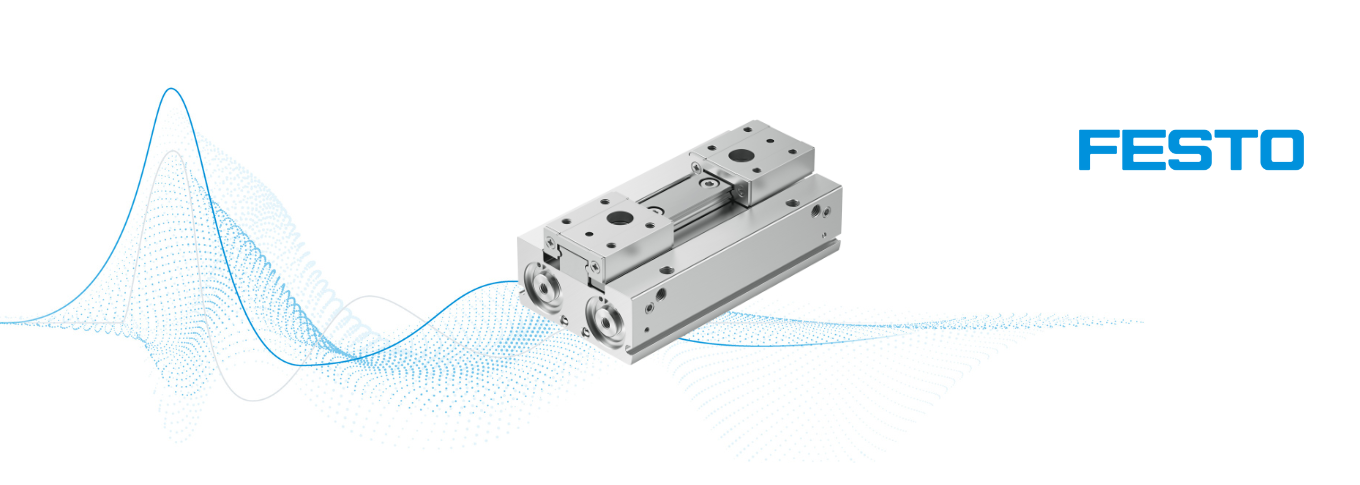

Festo Introduces a Flat Parallel Gripper for Space-Constrained Applications

From recently completed production lines, Festo introduces the HPPF, an innovative flat parallel gripper that ranges in height from 19 mm to 41 mm among its four sizes: 8, 12, 16, and 20. The stroke ranges from a narrow 8 mm to a wide 80 mm, and gripping forces span from 60 N to 377 N. HPPF flat parallel grippers are ideal in space-constrained applications for small parts and electronics assembly, including batteries due to low copper, zinc, and nickel content – less than 1%. These units are attractively priced thanks to manufacturing innovations.

Twin piston rack and pinion motion and ball bearing guides give these units high accuracy – ≤ 0.03 mm to ≤ 0.06 mm – and maintenance-free long-service life. Twin pistons provide these compact units with a high grip force. Units are symmetrical for flexibility in mounting. Both sides feature a C-slot for sensors. Machine builders can adjust the stroke and there is an elastic cushioning option. Weight is exceptionally low – ideal for today’s smaller footprint, more sustainable machines – 68 g for the smallest unit and up to 1,326 g for the largest.

For more information on this innovative flat parallel gripper and the advantages of working within the Festo ecosystem ‒ the ecosystem that leads to less engineering overhead, fast time to market, and seamless connectivity ‒ visit www.festo.com.

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For 100 years with more than 50 in the U.S., Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment. Through advanced technical and industrial education, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies.