Festo Launches its Revolutionary Electric and Pneumatic Automation Platform at Pack Expo 2023

Festo debuts at Pack Expo 2023 the company’s new distributed I/O solution, CPX-AP-A. With the introduction of CPX-AP-A, along with its established CPX-AP-I decentralized I/O, Festo now offers a range of electric and pneumatic automation solutions that is unmatched in North America in terms of performance, flexibility, cost savings, and engineering productivity. Festo shows CPX-AP-A plus the company’s extensive lines of integrated electric and pneumatic motion solutions at Pack Expo, September 11-13, Las Vegas Convention Center, Festo Booth #SL6160.

“The Festo AP backplane communications platform provides a central communication and data transfer I/O interface. It is a combination of everything that we’ve learned over the past 25 years of creating electric and pneumatic linear automation solutions,” said Tim Sharkey, Director of Electric Automation, Festo North America. “AP stands for Automation Platform and this backplane-based remote I/O system has been in development for a decade.”

Troy Manley, Sales Director Food and Packaging, Festo North America, added, “In an era that demands increased machine flexibility, adaptability, and capacity, Festo has taken decades of mechanical motion experience and applied it to the new AP Automation Platform, developing a flexible, low cost, easy-to-commission integrated platform of electric and pneumatic solutions.”

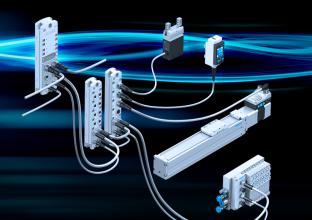

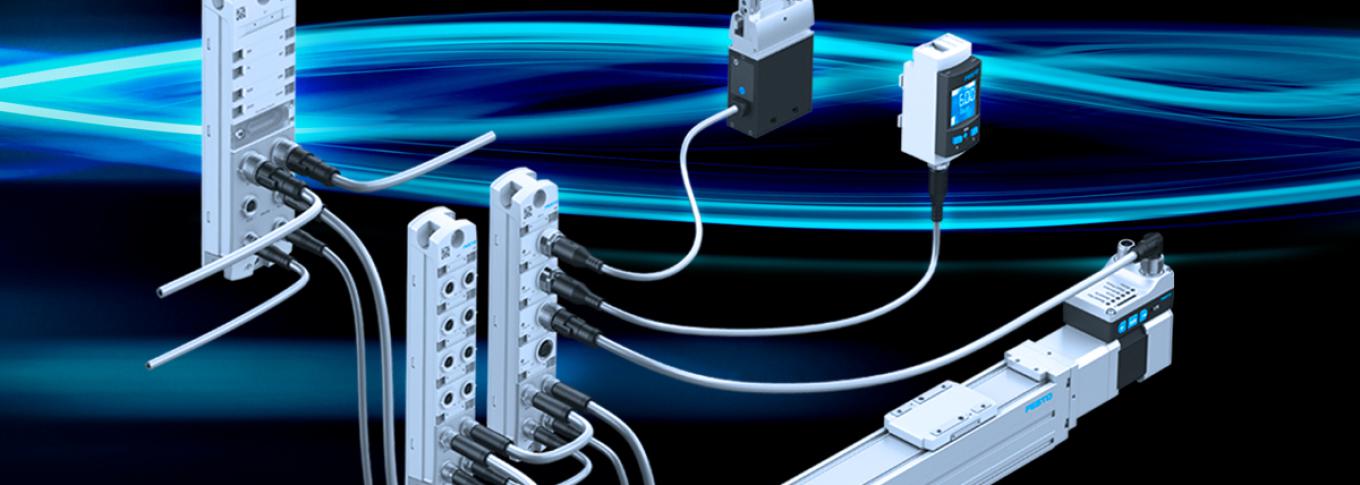

CPX-AP-A distributed I/O has modules attached within a terminal. CPX-AP-I is Festo’s decentralized I/O where modules are connected via cable at distances of up to 50 meters (164 feet) between modules. AP modules, whether on-terminal or individual, are IP65/67 rated and can be located in cabinets, in clusters around the cell, individually placed, or separated at great distances.

AP provides the utmost in topology flexibility. It gives machine builders the freedom to optimize the machine or cell by adding I/O where they need it, and in ways that will best boost performance and diagnostics capabilities. The AP ecosystem makes it efficient for end-user customers to add functionality as needs arise.

Whether physically attached on-terminal or connected via cable, all components such as PLCs, valves, motors, drives, and I/O appear to the programmer to be incorporated within one smart terminal under a single IP address. Having the entire distributed and decentralized I/O topology under a single IP address significantly reduces hardware and installation costs while lowering system complexity. Since many PLCs come with a limited number of IP addresses, the Festo solution means more capabilities are possible per PLC. The AP platform easily integrates electric and pneumatic automation directly into the higher-level control architectures – architectures from all major control suppliers.

Electric motion solutions featured

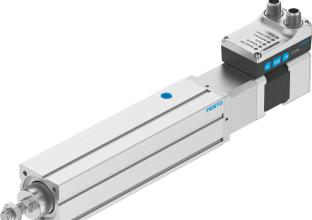

At Pack Expo, Festo also showcases its Simplified Motion Series (SMS) of integrated servo drives and linear and rotary actuators. SMS represents an engineering and price/performance breakthrough that combines the simplicity of pneumatics with the benefits of electric automation. SMS uses a range of proven actuators and integrates them with an onboard servo drive. Users commission two-position functionality via onboard push buttons with no additional software needed. When controlled with IO-Link, which is a standard feature of SMS axes, positioning along the axis length is infinitely variable.

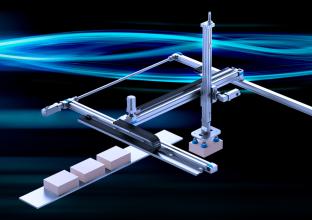

Festo multi-axis solutions shown at Pack Expo include a portfolio of rotary and linear single axes, multi-axis design tools, and cable management. All the axes are designed to integrate for quick assembly while expanding the range of multi-axis motion.

Festo features the new CMMT MP family of multi-protocol servo drives. Every drive in this family is configurable as EtherNet/IP, EtherCAT, PROFINET, and Modbus TCP. Using this single-family multi-protocol strategy, machine builders supporting multiple communications protocols can reduce servo-drive inventories. A unified drive family improves engineering productivity through familiarity with a single platform, simplifies tech support, and gains a robust supply chain for competitively priced servo drives. Festo showed the power of multi-protocol units by reducing its own part numbers from 24 to 8. CMMT MP drives are in stock and ready for shipment.

The latest mechatronic learning modules on display

In mid-2022, The Association for Packaging and Processing Technologies (PMMI – the organization behind Pack Expo), and Didactic, the training arm of Festo, joined forces to provide PMMI members and education partners with advanced technical education and hands-on training aligned with the industry’s highest standards. For the first time at Pack Expo, Didactic showcases its latest hands-on learning modules within the Festo exhibit. The MecLab integrated-packaging line learning modules consist of a conveyor, stack magazine, and handling station. Didactic also showcases its industry leading robotic safety learning system developed in collaboration with SICK, the technology and market leader in sensor intelligence.

For more information on the new Festo Automation Platform and the advantages of working within the Festo ecosystem ‒ the ecosystem that leads to less engineering overhead, fast time to market, and seamless connectivity ‒ visit www.festo.com.

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For 100 years with more than 50 in the U.S., Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment. Through advanced technical and industrial education, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies.