Festo Showcases Automated Battery Recycling at The Battery Show NA

Festo demonstrates at The Battery Show NA 2023 automated EV battery recycling – removal of batteries from housings and recovery of precious materials from shredded lithium-ion batteries. Festo also features a compact handling system for battery modules and electric and pneumatic automation solutions. The Battery Show NA, September 12-14, Suburban Collection Showplace, Novi, Michigan, Festo Booth #1545.

The automotive industry recognizes Festo as a leading automation supplier at every step of the EV battery process – material handling in a dry room, degassing, module assembly, and placement of housings on the vehicle frame. The automated materials recovery demonstration at The Battery Show illustrates Festo process solutions – solutions that can be applied to precious materials extraction as well as regeneration and recovery.

Handling and process automation solutions from Festo enable 360° support of the circular battery economy, an economy where repurposing and recycling EV batteries can decrease reliance on virgin materials, reduce impacts associated with extraction, and lower the risk of supply chain interruptions.

Recovery of precious materials

Festo controls and process valves simulate the automated extraction of precious materials from a slurry of shredded EV batteries. In this simulation of the actual process, acids are introduced into the slurry to precipitate precious materials out of the solution for ease of separation and collection. Valuable materials available for recapture and reuse in lithium-ion batteries include cobalt, gold, lithium, manganese, neodymium, nickel, palladium, platinum, silver, and tantalum. Key Festo components in the extraction demo include the CPX-MPA fieldbus-enabled valve terminal controller, the DFPC linear actuator for a knife gate valve, the KVZA pre-assembled process valve, and the VZXA angle seat valve.

Safe dismantling of battery modules

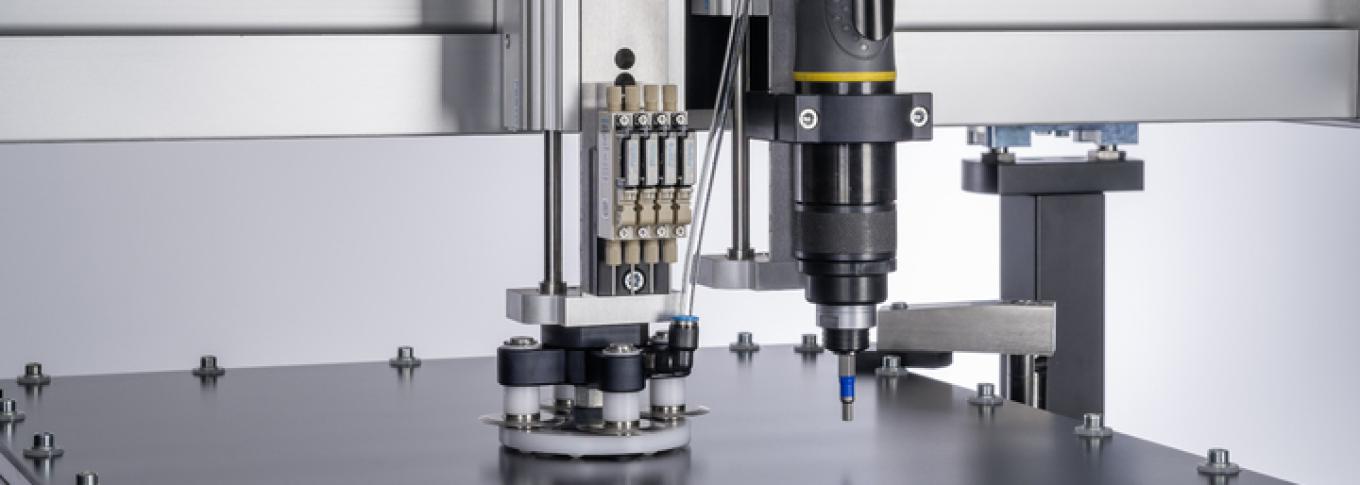

Disassembling the battery housing and removing modules and other components is a labor-intensive operation. The Festo dynamic display simulates the automated mechanical disassembly of battery housings into modules, battery cells, and other components. Key actions include:

- Checking the cooling circuit

- Cutting open the adhesive bead between the housing top and bottom

- Fixing the housing top into place

- Lifting the housing top

Machine builders will find the components and overall design of this solution accommodate a range of housings and battery types. Highlighted Festo components include: the VTOE dispense head, provides lubricant for the knives to prevent build up on the edges; the EFSD stopper cylinder, cushions and stops horizontal movement; the CLR linear/swivel clamp, guarantees precise fixing of the battery housing top; and the VAS suction cup that lifts the housing top gently and reliably.

The circular economy for batteries is essential for meeting the demands of the EV market

“In order to meet the needs of the rapidly growing EV market, the United States will need to expand battery recycling capabilities, as well as grow our domestic capacity for producing battery precursor materials,” said Jigar Shah, Director, Loan Programs Office at the U.S. Department of Energy. “By lowering the cost of the critical materials for lithium-ion batteries using recycled materials, electric vehicles can become more accessible to lower income communities.”

To jump start a robust recycling supply chain, The Inflation Reduction Act includes a clause that automatically qualifies EV battery materials recycled in the U.S. as American-made and eligible for subsidies, regardless of their origin. That approach qualifies automakers using U.S.-recycled battery materials for EV production incentives.

Not only must the supply chain for spent EV batteries be made robust and efficient, but also the process of recycling must be automated to achieve maximum productivity and throughput. Automation can help maintain a clean and safe working environment when handling battery materials. Festo contributes to the circular battery economy with electric and pneumatic automation solutions, application expertise, global supply chain, engineering productivity tools, and training.

Visit the Festo battery manufacturing webpage for more information. For the advantages of working within the Festo ecosystem ‒ the ecosystem that leads to less engineering overhead, fast time to market, and seamless connectivity ‒ visit www.festo.com.

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For 100 years with more than 50 in the U.S., Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment. Through advanced technical and industrial education, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies.