Festo invests to meet growing demand for electronics components

The semiconductor and electronics industries have set benchmarks for continuous innovation while keeping prices low. As digitalisation increases, electronic components are rapidly finding their way into other industries too. Sectors as diverse as the automotive industry, medical technology and distribution logistics are demanding more powerful electronics and sensors for applications ranging from self-driving vehicles to artificial heart valves. Traceability techniques pioneered in pharmaceuticals are now transferring to the food and packaging industries where smart, intelligent packaging equipped with electronic chips is being rapidly adopted.

For OEMs, this means developing ever faster and more productive machines and plants in timeframes of less than 18 months. This in turn is increasing demand for reliable, compact and cost-efficient automation components that are readily available. Indeed, compact automation technology from reliable partners is the key to success.

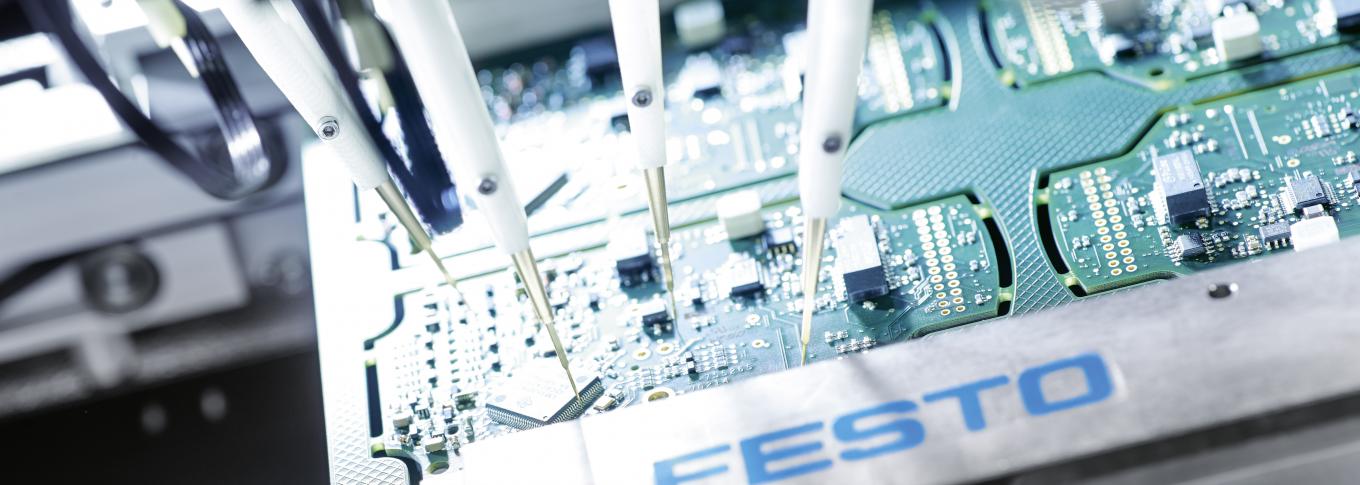

Industrial automation specialist Festo has invested significantly in its core product range and related manufacturing and supply network to ensure that its electronic components are readily available worldwide, offer a long service life and are attractively priced.

"Large quantities, high speed, worldwide availability and attractive prices are the minimum requirements for automation technology in the semiconductor industry and electronics manufacturing, as well as many other sectors. Festo has therefore doubled its production capacity worldwide with a focus on Asia, which means it is fully prepared for the high demand for electric and pneumatic standard products," explains Arian Scholz, Head of Global Key Account and Industry Segment Management at Festo.

Wide choice, rapid delivery

The automation components mentioned are part of the Festo core product range, with its distinctive blue star livery. These "Stars in Automation" comprise more than 2,200 components for every phase of the pneumatic and electrical control chain: from compressed air preparation, valves and cylinders to accessories, such as matching tubing and fittings.

Particularly attractive for the electronics industry are ADN compact cylinders, the DGST mini slide and the DFM guided drive, as well as matching proximity sensors, VUVG valves and the MS2 series of service units. All products enable a pneumatic control chain with a very compact design.

Many of the components marked with the star are ready to be shipped just 24 hours after the order is received, while configurable products are ready for delivery within five days. All products in the Festo core product range are available worldwide and with the same level of quality thanks to automated production at various decentralised locations in the core markets of Germany, China and the USA. There are also further production plants in India, Brazil, Hungary, the Czech Republic, Bulgaria and Switzerland. Distribution is also decentralised thanks to highly automated logistics centres in Germany, China and the USA, so 70% of all customers can be reached within one day.

Better by design

The hallmark of the latest components in the core product range is the collaboration between the design engineers and production planners at Festo. They worked closely together during the development of these products to ensure that the components can be manufactured in the Festo plants with a high degree of automation.

For the new DGST mini slide, for example, the yoke and slide are manufactured fully automatically as a single part. In addition, the developers successfully reduced the number of components by 60% compared with the previous model. This enables the DGST to be produced in large quantities with maximum efficiency. The same approach also allowed the cycle times for the DFM guided drive to be reduced by almost 50%. Festo plants can now produce a DFM every minute. Another example is the fully automated production line for the VUVG standard valve, which produces a fully assembled valve every 12 seconds.

About Festo

Festo is a leading international supplier of automation technology with a turnover in 2024 of around €3.45 billion. Festo employs over 20,000 people worldwide and is a proven innovator and problem solver in pneumatic and electrical automation, where it is the performance leader. Festo offers around 36,000 pneumatic and electric products in hundreds of thousands of variants for factory and process automation technology, many of which can be tailored to specific customer needs. Sustainability, reducing its CO2 footprint, digital learning, innovation, performance and speed are the key drivers for the company's future. Festo GB operates as a carbon neutral organisation and uses the PAS 2060 standard externally audited by NQA to validate this claim to customers, employees and other stakeholders.

Festo Industrial Automation's innovative strength is demonstrated through the launch of around 100 new products every year. The company invests over 8.5% of its turnover in R&D, resulting in over 2,600 patents held worldwide. For more information about the company's products and UK / Irish services, please visit: www.festo.com/gb and www.festo.com/ie

Festo and Industry 4.0 - Festo has engaged with the Industry 4.0 initiative from its inception: as a user, manufacturer and trainer. As a member of the steering group, the company has taken an active role in defining the core standards such as the RAMI model and the Administration Shell. Festo Didactic has installed Industry 4.0 Cyber-Physical Factory training hardware systems in many leading universities and training centres. It also provides Industry 4.0 training courses for change managers and practical workshops for employees. Industry 4.0 technologies such as OPC-UA communications are embedded in the latest generation products. For more information, go to www.festo.com/digitalisation

Festo Didactic training delivers training for industry – by industry. Combining Festo's industrial heritage with its future-focused manufacturing and engineering expertise to deliver courses for greater productivity and competitiveness. Offering a wide range of open courses, structured development programmes and tailor-made, customer-specific projects on technology and Industry 4.0 and the industry-leading online training suite, Festo LX. Festo also provides state-of-the-art training equipment solutions for industrial companies and educational institutions around the world. Festo Didactic has around 56,000 education customers worldwide. More information on Festo training and consulting services can be found at: www.festo.com/didactic

Festo Bionic Learning Network encapsulates the innovative nature of Festo, raising awareness and attracting talent to the company. Exploring the links between nature and technology opens new areas of innovation and demonstrates complex ideas in a stimulating and enjoyable way. Festo works with an alliance of internal R&D, external educational establishments and specialist companies to advance bionic solutions for automation applications of the future. The objective is to benefit from bionics as a source of inspiration and to realise these in industrial automation. For more information about Festo's Bionic Learning Network, please visit: www.festo.com/bionics