Festo introduces a compact servo drive for demanding positioning applications

Festo has expanded its range of servo drives with the introduction of the CMMT-ST. Complementing the existing CMMT-AS, this new servo drive is equally reliable but much more compact and economical. These characteristics make it ideal for point-to-point and interpolating motion in demanding applications in assembly and handling technology, packaging machines or in the electronics industry.

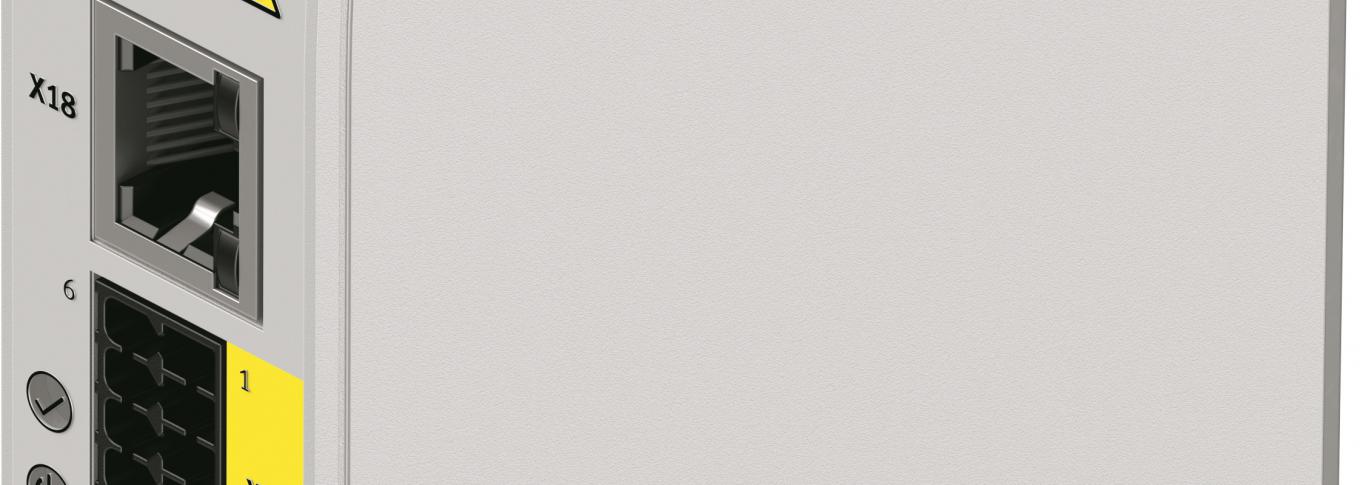

The CMMT-ST enables challenging dynamic motions for small servo motors and all stepper motors with a continuous power requirement of up to 300 W. It has a power capacity of 2.5 kW, so requires less cooling than its big brother and needs just half the installation space.

It is particularly suitable for various Ethernet-based bus systems and can be seamlessly integrated into the controller environments of different manufacturers. The CMMT-ST is based on the same platform as the CMMT-AS and works best in combination with the EMMS-ST stepper motor from Festo.

Quick commissioning

Commissioning the CMMT-ST takes just a few minutes with the Festo Automation Suite. Although the CMMT-ST offers a more compact, cheaper option than the CMMT-AS, the connection and communication concept, functional modules and standard safety features remain unchanged. The consistent control concept means that users can combine the CMMT-AS and CMMT-ST as a servo drive for both large and small axes.

The free Festo Automation Suite is the main software of the constantly expanding Festo Automation Platform, which is entering the automation market with numerous new products and solutions from the mechanical system to the cloud. It combines the parameterisation, programming and maintenance of electric components from Festo in one program. It also enables the entire drive package, from the mechanical system to the controller, to be commissioned in just a few intuitive steps.

Seamless connectivity

The CMMT-ST servo drive is an important part of the Festo philosophy of seamless connectivity: the ability to connect a workpiece completely through to the cloud, from its mechanical connections and electrical interfaces to commissioning and controller programming. Festo simplifies the work of machine builders and automation engineers with simple connectivity spanning mechanical, electrical, hardware and software interfaces.

About Festo

Festo is a leading international supplier of automation technology with a turnover in 2024 of around €3.45 billion. Festo employs over 20,000 people worldwide and is a proven innovator and problem solver in pneumatic and electrical automation, where it is the performance leader. Festo offers around 36,000 pneumatic and electric products in hundreds of thousands of variants for factory and process automation technology, many of which can be tailored to specific customer needs. Sustainability, reducing its CO2 footprint, digital learning, innovation, performance and speed are the key drivers for the company's future. Festo GB operates as a carbon neutral organisation and uses the PAS 2060 standard externally audited by NQA to validate this claim to customers, employees and other stakeholders.

Festo Industrial Automation's innovative strength is demonstrated through the launch of around 100 new products every year. The company invests over 8.5% of its turnover in R&D, resulting in over 2,600 patents held worldwide. For more information about the company's products and UK / Irish services, please visit: www.festo.com/gb and www.festo.com/ie

Festo and Industry 4.0 - Festo has engaged with the Industry 4.0 initiative from its inception: as a user, manufacturer and trainer. As a member of the steering group, the company has taken an active role in defining the core standards such as the RAMI model and the Administration Shell. Festo Didactic has installed Industry 4.0 Cyber-Physical Factory training hardware systems in many leading universities and training centres. It also provides Industry 4.0 training courses for change managers and practical workshops for employees. Industry 4.0 technologies such as OPC-UA communications are embedded in the latest generation products. For more information, go to www.festo.com/digitalisation

Festo Didactic training delivers training for industry – by industry. Combining Festo's industrial heritage with its future-focused manufacturing and engineering expertise to deliver courses for greater productivity and competitiveness. Offering a wide range of open courses, structured development programmes and tailor-made, customer-specific projects on technology and Industry 4.0 and the industry-leading online training suite, Festo LX. Festo also provides state-of-the-art training equipment solutions for industrial companies and educational institutions around the world. Festo Didactic has around 56,000 education customers worldwide. More information on Festo training and consulting services can be found at: www.festo.com/didactic

Festo Bionic Learning Network encapsulates the innovative nature of Festo, raising awareness and attracting talent to the company. Exploring the links between nature and technology opens new areas of innovation and demonstrates complex ideas in a stimulating and enjoyable way. Festo works with an alliance of internal R&D, external educational establishments and specialist companies to advance bionic solutions for automation applications of the future. The objective is to benefit from bionics as a source of inspiration and to realise these in industrial automation. For more information about Festo's Bionic Learning Network, please visit: www.festo.com/bionics