New VYKA media separated valve range from Festo

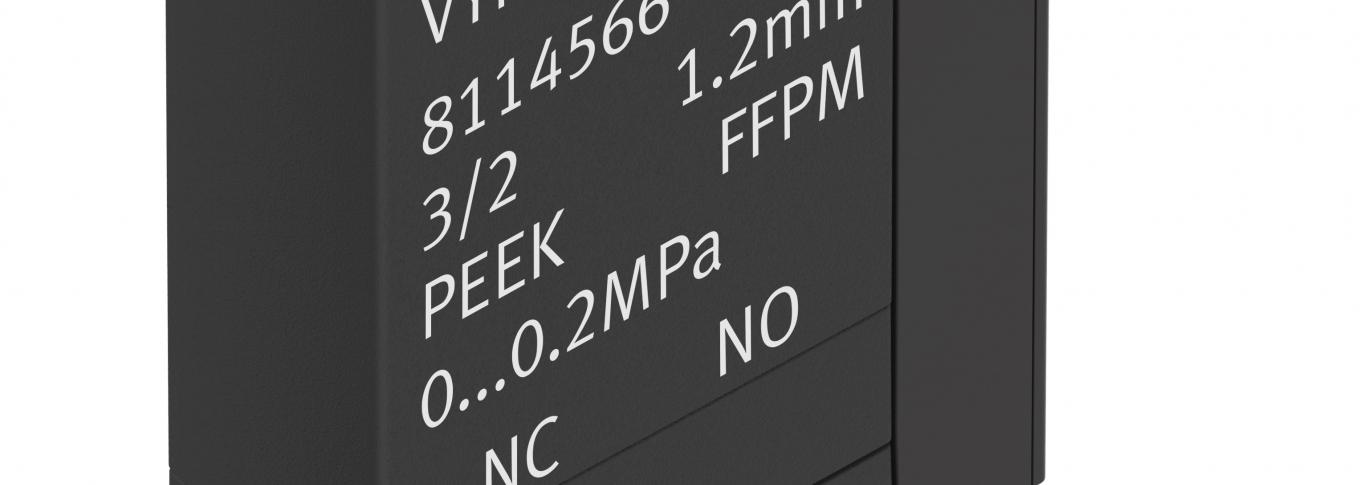

Industrial automation specialist Festo has introduced the VYKA range of media separated solenoid valves offering high precision control of virtually any fluid or gas. Just 7mm in width and with an orifice size of 1.2mm, the VYKA range has a class leading pressure-to-orifice size ratio and offers a compact solution to a wide variety of dosing and continuous flow applications.

Suitable for use as dosing valves for contactless dispensing or as control valves for continuous flow applications, the VYKA range owes its excellent chemical resistance to the fact it is constructed from inert materials. Separating diaphragms made of high-performance FKM and FFKM polymers mean that the valves can be used safely with very aggressive media, providing protection whilst simultaneously preventing corrosion. This makes them an excellent choice for electronics and semiconductor manufacturing, including wafer production and deposition, as well as printing applications.

Pharmaceuticals, medtech and food manufacturing will also benefit from the control accuracy and compact size of VYKA valves. Uniquely, the valves’ wetted materials are FDA listed and their low internal volume makes them very easy to clean: a real boon in reducing valuable media losses, or for sensitive and hygienic environments. Typical applications include liquids handling in laboratory automation, in-vitro diagnostics and high-precision filling applications with sensitive and aggressive media (such as perfumes and aromatics, or packaging contact lenses).

Pressures of up to 4 bar and a flow rate of up to 350 ml/min are not a problem for VYKA solenoid valves. They utilise current control, which significantly improves the reproducibility of the switching behaviour critical to delivering highly accurate results. When a VYKA valve is used in conjunction with compatible Festo connectors and controllers, a holding current reduction from 0.3W down to 0.06W can be achieved, reducing heat build-up and preventing thermal transfer to sensitive media passing through the valve.

The VYKA range is extremely flexible thanks to its 3/2, 2/2 (NC/NO) variants. Festo also offers a powerful range of accessories, greatly extending the performance and capabilities of the VYKA range. These include a variety of electrical connection options through the VAVE electrical connection box with integrated holding current reduction. The VAEM valve control module for up to eight valves enables even higher dispensing precision by accurately controlling pulse durations down to 2ms repeatability. The range is completed with NLFA liquid compatible fittings, VAVN dosing nozzles and the VABS PEEK material connection module – so that machine builders and OEMs can source everything they require to meet demanding end-user specifications.

About Festo

Festo is a leading international supplier of automation technology with a turnover in 2024 of around €3.45 billion. Festo employs over 20,000 people worldwide and is a proven innovator and problem solver in pneumatic and electrical automation, where it is the performance leader. Festo offers around 36,000 pneumatic and electric products in hundreds of thousands of variants for factory and process automation technology, many of which can be tailored to specific customer needs. Sustainability, reducing its CO2 footprint, digital learning, innovation, performance and speed are the key drivers for the company's future. Festo GB operates as a carbon neutral organisation and uses the PAS 2060 standard externally audited by NQA to validate this claim to customers, employees and other stakeholders.

Festo Industrial Automation's innovative strength is demonstrated through the launch of around 100 new products every year. The company invests over 8.5% of its turnover in R&D, resulting in over 2,600 patents held worldwide. For more information about the company's products and UK / Irish services, please visit: www.festo.com/gb and www.festo.com/ie

Festo and Industry 4.0 - Festo has engaged with the Industry 4.0 initiative from its inception: as a user, manufacturer and trainer. As a member of the steering group, the company has taken an active role in defining the core standards such as the RAMI model and the Administration Shell. Festo Didactic has installed Industry 4.0 Cyber-Physical Factory training hardware systems in many leading universities and training centres. It also provides Industry 4.0 training courses for change managers and practical workshops for employees. Industry 4.0 technologies such as OPC-UA communications are embedded in the latest generation products. For more information, go to www.festo.com/digitalisation

Festo Didactic training delivers training for industry – by industry. Combining Festo's industrial heritage with its future-focused manufacturing and engineering expertise to deliver courses for greater productivity and competitiveness. Offering a wide range of open courses, structured development programmes and tailor-made, customer-specific projects on technology and Industry 4.0 and the industry-leading online training suite, Festo LX. Festo also provides state-of-the-art training equipment solutions for industrial companies and educational institutions around the world. Festo Didactic has around 56,000 education customers worldwide. More information on Festo training and consulting services can be found at: www.festo.com/didactic

Festo Bionic Learning Network encapsulates the innovative nature of Festo, raising awareness and attracting talent to the company. Exploring the links between nature and technology opens new areas of innovation and demonstrates complex ideas in a stimulating and enjoyable way. Festo works with an alliance of internal R&D, external educational establishments and specialist companies to advance bionic solutions for automation applications of the future. The objective is to benefit from bionics as a source of inspiration and to realise these in industrial automation. For more information about Festo's Bionic Learning Network, please visit: www.festo.com/bionics