Festo Controlled Pneumatics

Controlled Pneumatics is the rapidly evolving compressed air technology from Festo that is opening new applications for pneumatics. The technology delivers more precision and control than ever, while having the potential to dramatically reduce energy use. This is clearly demonstrated in the VTEP: the first proportional valve terminal on the market, offering high precision, fast response times, and dynamic control.

Thanks to this technology, the VTEP provides extremely sensitive pressure control, down to less than 1 mbar — perfect for applications such as wafer polishing or patch clamping in life science. In addition, Controlled Pneumatics from Festo uses high-precision piezo valves to reduce compressed air consumption by up to 50%. This level of control enables the VTEP to speed-up production while ensuring that manufactured goods are of a higher quality.

The VTEP is an example of how Festo industrial automation technology makes machines and systems faster and more precise, helping customers in the electronics and semiconductor industries, battery production, life sciences, textile manufacturing, and others to gain decisive competitive advantages.

Pressure or vacuum? Both!

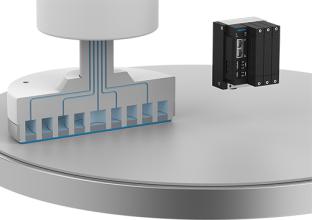

At less than 120mm wide, the VTEP is the most compact proportional valve terminal on the market for pressure control with 10 independent work channels. There are three versions, with 2-, 3-, and 5-valve positions, which can all be easily integrated for multi-channel applications. Pressure and vacuum can be combined in the control range of -1 up to 6 bar positive pressure. The individual valves can be controlled to control the pressure, block, or exhaust the system pressure.

The directly controlled VTEP uses piezo technology which, together with the appropriate control technology, makes the pneumatics extremely precise, fast, and economical. Additional benefits include a valve that is quiet, free of wear, and has no particle abrasion.They also don't generate any heat, which delivers more stable control behaviour over time. The proportional valve terminal is also free of copper, nickel, and zinc, making it very suitable for battery production and other industrial segments in which these materials are disruptive.

Wafers, batteries, and more

During wafer production, the variable contact pressure of the individual polishing chambers on the polishing unit can be controlled extremely precisely by the VTEP. The even pressure guarantees excellent quality results across the entire processing surface, even when polishing delicate wafers. VTEP terminal valves can also be used as pilot valves for larger media valves. In photolithography, for example, a light-resistant layer has to be precisely applied to wafers. A VTEP-controlled suck-back function ensures that no excess coating escapes.

The VTEP proportional valve terminal is also suitable for many applications in web control, such as the production of battery foils. VTEP communicates over Ethercat in real time, and the valves react at lightning speed. Perfect timing guarantees significantly improved process reliability in the event of unexpected forces acting on the web.

Controlled Pneumatics is breathing fresh energy into pneumatics, precisely metering and controlling compressed air and neutral gases. The VTEP proportional valve terminal is an exciting contribution, combining several valves together into a compact and easily controlled solution that is easier and faster for machine builders to integrate into their control architecture.

About Festo

Festo is a leading international supplier of automation technology with a turnover in 2024 of around €3.45 billion. Festo employs over 20,000 people worldwide and is a proven innovator and problem solver in pneumatic and electrical automation, where it is the performance leader. Festo offers around 36,000 pneumatic and electric products in hundreds of thousands of variants for factory and process automation technology, many of which can be tailored to specific customer needs. Sustainability, reducing its CO2 footprint, digital learning, innovation, performance and speed are the key drivers for the company's future. Festo GB operates as a carbon neutral organisation and uses the PAS 2060 standard externally audited by NQA to validate this claim to customers, employees and other stakeholders.

Festo Industrial Automation's innovative strength is demonstrated through the launch of around 100 new products every year. The company invests over 8.5% of its turnover in R&D, resulting in over 2,600 patents held worldwide. For more information about the company's products and UK / Irish services, please visit: www.festo.com/gb and www.festo.com/ie

Festo and Industry 4.0 - Festo has engaged with the Industry 4.0 initiative from its inception: as a user, manufacturer and trainer. As a member of the steering group, the company has taken an active role in defining the core standards such as the RAMI model and the Administration Shell. Festo Didactic has installed Industry 4.0 Cyber-Physical Factory training hardware systems in many leading universities and training centres. It also provides Industry 4.0 training courses for change managers and practical workshops for employees. Industry 4.0 technologies such as OPC-UA communications are embedded in the latest generation products. For more information, go to www.festo.com/digitalisation

Festo Didactic training delivers training for industry – by industry. Combining Festo's industrial heritage with its future-focused manufacturing and engineering expertise to deliver courses for greater productivity and competitiveness. Offering a wide range of open courses, structured development programmes and tailor-made, customer-specific projects on technology and Industry 4.0 and the industry-leading online training suite, Festo LX. Festo also provides state-of-the-art training equipment solutions for industrial companies and educational institutions around the world. Festo Didactic has around 56,000 education customers worldwide. More information on Festo training and consulting services can be found at: www.festo.com/didactic

Festo Bionic Learning Network encapsulates the innovative nature of Festo, raising awareness and attracting talent to the company. Exploring the links between nature and technology opens new areas of innovation and demonstrates complex ideas in a stimulating and enjoyable way. Festo works with an alliance of internal R&D, external educational establishments and specialist companies to advance bionic solutions for automation applications of the future. The objective is to benefit from bionics as a source of inspiration and to realise these in industrial automation. For more information about Festo's Bionic Learning Network, please visit: www.festo.com/bionics