New ELGD mechanical axis series from Festo

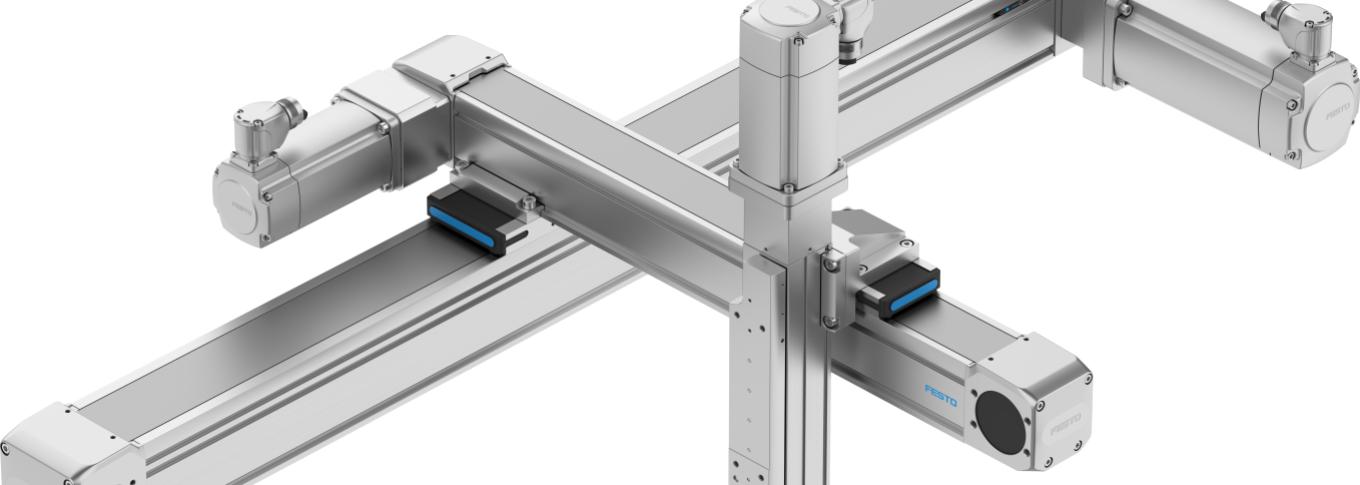

Machine builders and systems installers are under pressure to deliver high performance automation solutions that are quicker to deploy and offer a low total cost of ownership. Industrial automation specialist Festo has developed its new ELGD mechanical axis series to meet these demands. Specifically designed for tooth belt and ball screw mechanical axes in cartesian handling systems, the ELGD series features a simplified design that delivers exceptional load bearing capacity, a longer service life and increased reliability in multiple industrial handling situations, from harsh to hygienic environments.

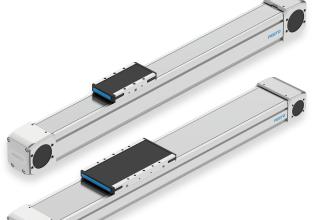

The ELGD-BS spindle drive offers a configurable stroke range of up to 2.5m and the ELGD-TB toothed belt drive has a stroke length of up to 8.5m. Both are available in a range of different sizes in either standard square profile or a wide profile that offers a height saving of 30 percent. All variants provide excellent rigidity, large feed forces and high precision.

Suited to most electromechanical handling tasks, the ELGD axis series brings specific benefits to applications such as:

- cantilever systems and pick-and-place solutions for small parts handling, where short cycle times, high precision and repeatability are key;

- handling systems for top loaders, which will benefit from the ELGD’s attractive cost/performance ratio, high travel speed and long stroke lengths;

- automation of 3D printing and additive manufacturing, which requires very dynamic, virtually vibration-free movement in a harsh operating environment.

Smaller, more powerful axis

Outstanding mechanical performance is combined with an optimised design for the internal structure, which means it takes up less space inside the ELGD axis. As a result, it is possible to accommodate an even more powerful tooth belt or ball screw to achieve greater feed forces and acceleration profiles. A very compact design also raises the potential to use a smaller size ELGD axis than standard equivalents to reduce your handling solution’s weight, installation size and overall cost.

The ELGD series offers a choice of carriage options, including a long carriage and additional passive carriage. The long carriage integrates a second pair of split ball bearing cartridges, which provides even greater permissible torques to the carriage for the most demanding applications. The passive second carriage allows the loads on the guidance to be distributed even further, thus improving the maximum permissible torque and subsequent service life for the mechanics in the application.

The ELGD also features a stainless steel cover strip, which minimises particle emissions in cleanroom applications and reduces ingress of particles in harsh environments. This feature is further enhanced by the inclusion of a pneumatic connection to provide a sealing air (0.1 – 0.2 Bar) or a vacuum to the internal structure of the mechanics. Another innovation is the magnetic deflection of the cover strip, which eliminates mechanical wear to further reduce the likelihood of particle emissions.

Simplified design and assembly

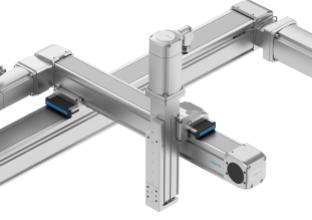

When designing cartesian solutions, a significant amount of time and money can be spent on designing bespoke brackets to connect the various mechanical axis together. The ELGD overcomes this by offering direct mounting options between various sizes and using standard brackets from the Festo catalogue to connect them together, simplifying your cartesian design.

Even greater time savings will be possible later in 2024, when the new ELGD axis series is integrated into the Festo Handling Guide Online (HGO). The HGO enables users to design a complete cartesian solution in around 10 minutes, complete with all documentation.

About Festo

Festo is a leading international supplier of automation technology with a turnover in 2024 of around €3.45 billion. Festo employs over 20,000 people worldwide and is a proven innovator and problem solver in pneumatic and electrical automation, where it is the performance leader. Festo offers around 36,000 pneumatic and electric products in hundreds of thousands of variants for factory and process automation technology, many of which can be tailored to specific customer needs. Sustainability, reducing its CO2 footprint, digital learning, innovation, performance and speed are the key drivers for the company's future. Festo GB operates as a carbon neutral organisation and uses the PAS 2060 standard externally audited by NQA to validate this claim to customers, employees and other stakeholders.

Festo Industrial Automation's innovative strength is demonstrated through the launch of around 100 new products every year. The company invests over 8.5% of its turnover in R&D, resulting in over 2,600 patents held worldwide. For more information about the company's products and UK / Irish services, please visit: www.festo.com/gb and www.festo.com/ie

Festo and Industry 4.0 - Festo has engaged with the Industry 4.0 initiative from its inception: as a user, manufacturer and trainer. As a member of the steering group, the company has taken an active role in defining the core standards such as the RAMI model and the Administration Shell. Festo Didactic has installed Industry 4.0 Cyber-Physical Factory training hardware systems in many leading universities and training centres. It also provides Industry 4.0 training courses for change managers and practical workshops for employees. Industry 4.0 technologies such as OPC-UA communications are embedded in the latest generation products. For more information, go to www.festo.com/digitalisation

Festo Didactic training delivers training for industry – by industry. Combining Festo's industrial heritage with its future-focused manufacturing and engineering expertise to deliver courses for greater productivity and competitiveness. Offering a wide range of open courses, structured development programmes and tailor-made, customer-specific projects on technology and Industry 4.0 and the industry-leading online training suite, Festo LX. Festo also provides state-of-the-art training equipment solutions for industrial companies and educational institutions around the world. Festo Didactic has around 56,000 education customers worldwide. More information on Festo training and consulting services can be found at: www.festo.com/didactic

Festo Bionic Learning Network encapsulates the innovative nature of Festo, raising awareness and attracting talent to the company. Exploring the links between nature and technology opens new areas of innovation and demonstrates complex ideas in a stimulating and enjoyable way. Festo works with an alliance of internal R&D, external educational establishments and specialist companies to advance bionic solutions for automation applications of the future. The objective is to benefit from bionics as a source of inspiration and to realise these in industrial automation. For more information about Festo's Bionic Learning Network, please visit: www.festo.com/bionics