Standardisation benefits all packaging lines

Standardisation is a recipe for success for a fruitful collaboration between packaging machine manufacturers and automation specialists. The strategic partnership between Syntegon and Festo is a great example of this. Thanks to this cooperation, Syntegon was able to simplify its processes and manage the challenges posed by the pandemic and the supply chain crisis more effectively.

Festo successfully mastered the global supply crisis triggered by the shortage of electronic components. "When there were bottlenecks that were caused by missing components, Festo proactively searched for alternative solutions with our engineers and usually found them quickly," explains Andreas Bäuerle, Strategic Procurement Manager at Syntegon.

Connection to many host controllers

Festo has provided Syntegon with an on-site team that supports and advises all Syntegon plants for machine and system building in Europe, America and Asia. With standardisation tools that are specific to Syntegon, Festo is making an important contribution to standardisation and thus also to Syntegon's profitability. The Festo automation platform helps machine builder Syntegon to connect to different host controllers without having to change the machine's drive elements.

Open interfaces

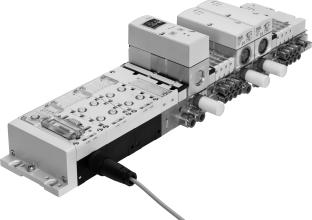

The machine controller is based on electric and pneumatic components and modules from the Festo automation platform, thus ensuring consistency on the supply side, since Festo products are available worldwide and offer open interfaces to higher-level control systems. The Festo automation platform is open for PROFINET, EtherCAT® and, especially for the North American market, also EtherNet/IP. Furthermore, component standardisation speeds up the time to market, which is a crucial competitive advantage. Open interfaces and faster time to market – these are increasingly important arguments for Syntegon in all international markets.

An example of this is the Manual Assembly Machine RMA, which is the heart of the Syntegon auto-injector assembly and labelling machine [for more information about this machine please read: The fast way to a safe insulin pen | Press (festo.com)]. The modular RMA (Range Manual Assembly) for auto-injectors, pens, needle protection systems and other medical devices is a pilot system for clinical trials and small batch sizes. It has a workstation for manually loading and unloading components and devices. All further process steps are executed automatically. The manual workstation thus achieves an output of one to three devices per minute.

Modular servo press system ensures quality

The modular servo press system YJKP, which is also part of the Festo automation platform, is used here. The modular servo press system is a pre-configured modular system consisting of software, controller and standard electric drives. Thanks to pre-installed software, it can be easily integrated into any system. This means that the modular press-fitting system with servo drive for electric press-fitting and joining up to 17 kN is immediately ready for use. Compared to similar solutions on the market, it is intuitive to parameterise and is cost-effective – training is not necessary. The precisely adjustable press-fitting and joining forces ensure consistent quality and low reject rates.

Insulin pens for self-medication, for example, need to be safe and user-friendly, i.e. they must not break when used by the patient and thus endanger the patient. The Festo Servo Press Kit avoids such product errors in the manufacturing process, as it keeps a constant tension and pressure in the production process.

Proportional valves ensure reliability

The drum coater Sepion 175 is used for coating tablets with films and sugar. It is the smallest size in the Sepion range, which offers drum sizes from 175 to 1000 litres. The Sepion Coater allows maximum flexibility (10-100%) of the batch size as well as high spray rates and thus short process times. The distance from the nozzles to the tablet bed is automatically set via the recipe.

The standard valve terminal MPA from Festo with integrated proportional valves performs crucial functions: it ensures the correct shape of the spray jet and optimum atomisation of the spray medium. It also controls the inflatable seals of the front and side doors, guaranteeing closed process control, which also meets the containment requirements for highly potent active ingredients. During recipe-controlled cleaning, the Festo valve terminal switches the valves for the different cleaning zones, resulting in effective cleaning and reproducible results.

"With the Sepion 175, we are specifically targeting pharmaceutical manufacturers who need a flexible and efficient coating solution for small production batches," says Fritz-Martin Scholz, Product Manager at Syntegon. "The Sepion Coater offers both thanks to modern controllers as well as the innovative drum design."

Flexibility with grippers

A flexible end-to-end packaging line packs coffee beans into stand-up pouches. The product handling system brings together products from two infeed lines, monitors the quality and transports them to a case packer for end of line packaging. The Elematic 3001 WAH case packer inserts two sizes of ten or eight stand-up pouches with coffee into one carton.

In addition to its high level of flexibility for numerous product sizes, the case packer makes an important contribution to sustainability: it uses corrugated cardboard made from recycled and alternative packaging materials, for example based on grass, coconut or cup plant (silphia). The electric parallel gripper EHPS from Festo also contributes to this flexibility, as it reliably adapts the gripping force to sensitive workpieces. The gripper's control is also flexible – either via digital I/O or IO-Link – and an external controller is not required.

About Syntegon:

Process and packaging technology for a better life – that is what 5,800 Syntegon employees work for every day. Whether with stand-alone machines, systems or services, Syntegon helps its customers in the food and pharmaceutical industries around the globe to improve people's lives. The company, with its corporate head office in Waiblingen near Stuttgart, has more than 160 years of experience and generated an annual turnover of 1.4 billion euros in 2021. In the pharmaceutical industry, intelligent solutions from Syntegon enable the safe and high-quality production, processing, filling, inspection and packaging of liquid and solid pharmaceuticals. In the food industry, the company's flexible and reliable technologies produce and package confectionery, dry food, frozen food and dairy products. With 1,100 service experts and a comprehensive range of services that covers the entire machine life cycle from spare parts management to digital line optimisation, Syntegon creates the basis for smooth production processes for its customers. At the same time, the company, with over 30 locations in almost 20 countries, has a firm eye on its impact on the environment and society. Syntegon is a leader in developing sustainable packaging solutions, reducing the energy consumption of its machines and pursuing ambitious targets to reduce its emissions.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。