Gentle and reliable wafer handling

The Festo Motion Terminal VTEM combines digitalisation and pneumatics. Quickly activated Motion Apps are revolutionising pneumatics by increasing flexibility and energy efficiency, and accelerating production processes. This also benefits electronics manufacturing, as demonstrated by the use of the automation platform VTEM in wafer handling.

The Festo Motion Terminal VTEM is moving pneumatics into the age of Industry 4.0 ‒ with apps that can replace over 50 individual components. Just as the smartphone turned the mobile communication market on its head over a decade ago, so too is the Festo Motion Terminal set to revolutionise automation technology. This new type of function integration – combined with software – simplifies the entire value chain, since only one piece of hardware is now required.

This means that users can execute different tasks with just one valve and operate 16 pressure regulation channels with eight valves. This significantly reduces the amount of work required, from engineering to format change-overs. This is why experts are calling the Festo Motion Terminal VTEM a revolution in automation technology.

Two Motion Apps for gentle and precise movements

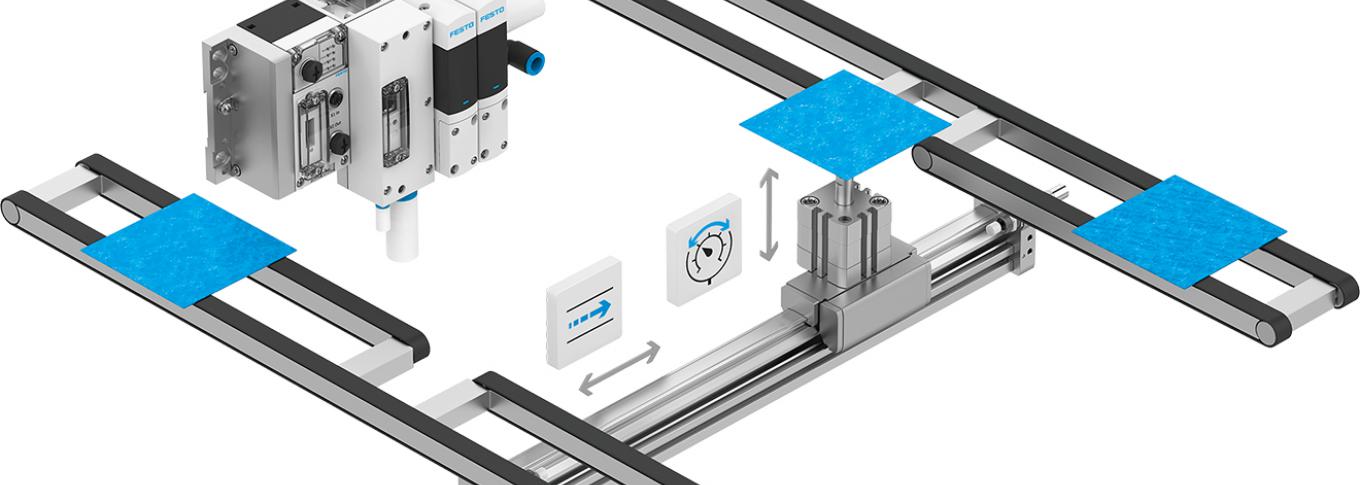

In an application from the electronics industry, a handling system for wafers with Z- and X-axes uses a compact cylinder AEN and a linear actuator DGC from Festo. They transport the wafers gently and reliably thanks to the two Motion Apps “Positioning” and “Proportional pressure regulation”.

The Motion App "Proportional pressure regulation” controls the advance movement of the actuator and regulates the vacuum used to grip the wafers. The Motion App “Positioning” moves the axis quickly and with minimal vibration to the next belt using full stroke measurement. It is now also possible to realise intermediate positions using this app. If the focus is on longer cylinder strokes and movement without intermediate positions, the Motion App “Soft Stop” with partial stroke measurement is ideal.

Positioning using pneumatics

With the Motion App “Positioning”, pneumatic actuators can be freely positioned along the entire working stroke and the cylinder movement can be controlled using limit values for the speed, acceleration and jerk parameters. Dynamic setpoints for position and maximum speed thus enable positioning tasks to be highly customised. The application ensures the correct motion speed and low impact energy in point-to-point movements while cycle times can be reduced with pre-positioning.

Pressure and vacuum control

Using the Motion App “Proportional pressure regulation”, both valve channels can now be regulated independently of each other. The first working channel moves a single-acting cylinder AEN in the Z direction using pressure regulation, while the second working channel gently places the wafer down using precisely metered vacuum regulation. The integrated system approach combines the fieldbus communication for all functions into one fieldbus device. This enables both cost and space savings.

Software instead of hardware

Thanks to the fast activation of new functions via Motion Apps, machine developers can create a basic machine type using the Festo Motion Terminal and then select the relevant Motion Apps to equip it with different functions and features as per the customer requirements. The ability to copy and transfer parameter sets makes planning easier and saves time. Assigning functions via software has the added benefit of preventing tampering and protecting know-how, since it’s not possible to tell from the outside which functions the valves are executing.

Maintenance is also simplified, as leaks are automatically monitored and long lists of spare and wearing parts are a thing of the past. Using the Motion App “Leakage diagnostics”, malfunctions can be detected and pinpointed to a specific actuator via diagnostic cycles and defined threshold values. This enables predictive maintenance.

New: Demo licence for other Motion Apps

Anyone choosing to purchase a Festo Motion Terminal at the moment will also receive a 30-day demo licence free of charge. This can be used to try out additional Motion Apps from “Directional control valve functions” to “ECO drive”.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.