Festo’s new ELGT cantilever electro-mechanical drive

Industrial automation specialist Festo has introduced a new cantilever electro-mechanical drive that is designed to meet the demanding specifications of modern production facilities. The new ELGT drive combines precision with high load-bearing capacity and rigidity, which makes it ideal for small parts and Lithium-ion battery manufacturing.

The ELGT is a powerful yet highly cost-effective addition to the range of Festo electro-mechanical axes. It easily combines with the existing ranges to provide customers with more choice and a lower-cost solution for cantilever axis applications. Festo’s manufacturing standards further ensure that copper and zinc content in the ELGT is less than 1%, meeting the requirements of the battery production sector to minimise contamination.

Flexibility and performance

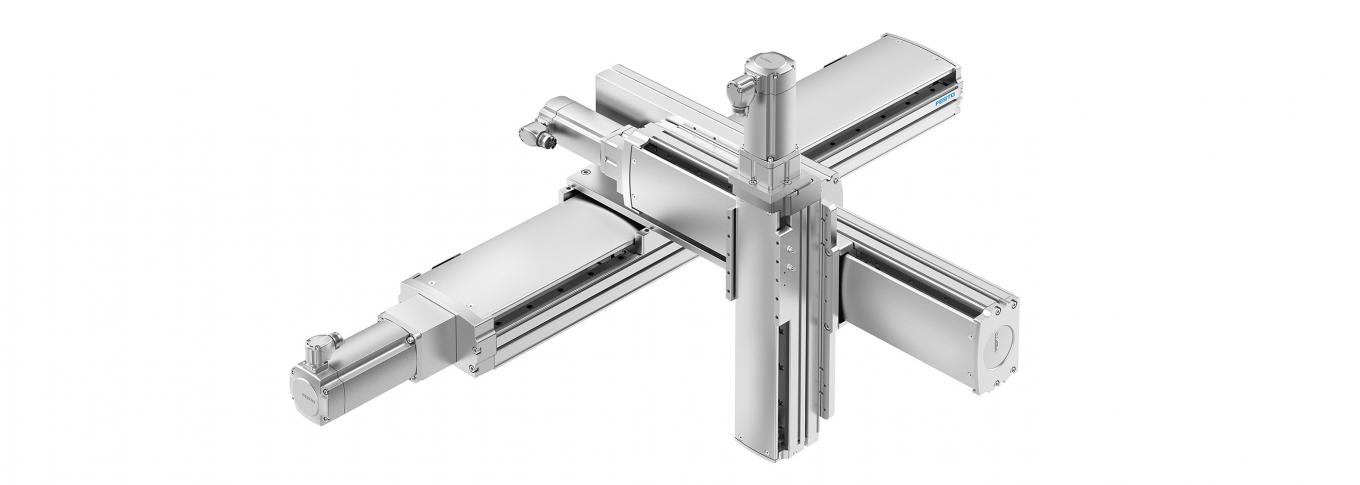

At the ELGT’s core is a precision spindle drive with the load supported by integrated twin bearing guides. This helps to ensure that the interfaces enabling the X, Y and Z axes interconnections are lightweight and extremely sturdy: maintaining rigidity and repeatability of positioning accuracy, even under heavier loads.

ELGT axes are available in three widths of 90, 120 and 160 mm, making this drive equally suitable for 2D and 3D cantilever systems. The size 90 comes with an extra wide single guide, while the 120 and 160 sizes have a twin guide. The largest axis can carry loads of up to 600 kg at speeds of up to 1 m/s and accelerations of up to 15 m/s. Depending on model choice, stroke lengths of between 50 mm and 1500 mm are available in 50 mm increments.

For maximum flexibility, the ELGT offers three mounting options: a direct screw connection into the precisely machined and threaded base, adjustable slot nuts that can be slid along the profile body, or brackets for mounting from the side. Users can also choose from a variety of motor drive options. The ELGT can be supplied without motors, or with a choice of stepper or servo motors. Motors can be positioned at 0,90,180 or 270o.

Open connectivity

Where end customers have a company standard or strong preference for alternative motor suppliers (often dependent on the final destination of the machinery), standard motor kits are available for most leading brands including Siemens, Omron, Mitsubishi and Yaskawa. The same applies to sensors; there are easy mountings for standard Festo sensors for homing and position registration, and additional brackets are also available for other manufacturers' sensors.

Simple configuration

Whether the key criteria be speed, precision, cost or size, customers can easily mix Festo stepper and servo motors within a multi-axis handling system to achieve the desired performance. They use the same easy programming language, and the set-up within the Festo Automation Suite configuration software is identical.

Festo’s free of charge Electric Motion Sizing (EMS) software makes selection even quicker and easier by enabling calculation of single axis applications and the Handling Guide Online [HGO] software package enables systems from single-axis to a 3D gantry or cantilever system to be designed by the user in under 15 minutes, complete with 3D CAD drawings. The next release of HGO will incorporate the new ELGT cantilever axes.