Measuring, weighing and transporting without contact

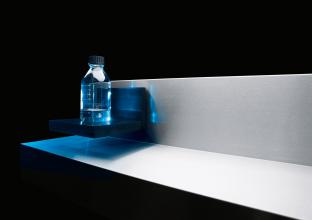

Highly pure, sterile processes are a key challenge for the industrial production – especially in food processing and the pharmaceuticals and medical technology industries, but also in the electronics sector. To keep manufacturing processes as free from contamination as possible, the workpieces and the workroom should be separated from each other. This can be achieved with superconductor-based levitation. Festo will be showing its concept for non-contact weighing and measuring at Achema 2022.

Highly pure, sterile processes are a key challenge for the industrial production of tomorrow – especially in food processing and the pharmaceuticals and medical technology industries, but also in the electronics sector. To keep manufacturing processes as free from contamination as possible, the workpieces and the workroom should be separated from each other. This can be achieved with superconductor technology. At the Hannover Messe 2018 trade fair, Festo is presenting a concept for contact-free weighing and measuring and another one for moving objects with a large hovering gap.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.