Measuring and weighing without contact

Highly pure, sterile processes are a key challenge for the industrial production – especially in food processing and the pharmaceuticals and medical technology industries, but also in the electronics sector. To keep manufacturing processes as free from contamination as possible, the workpieces and the workroom should be separated from each other. This can be achieved with superconductor-based levitation. Festo will be showing its concept for non-contact weighing and measuring at Achema 2022.

Particularly in cleanrooms, surfaces must be sealed, and be able to be easily and effectively cleaned and disinfected. The working equipment present the biggest challenge here: from test tubes to distillation columns, they are introduced from the outside and can bring in germs. Moreover, the contact surfaces on their bases develop minute cracks that are difficult to keep clean. The use of levitation technology based on magnetic fields – for example superconductor technology – can dispense with such problems in future.

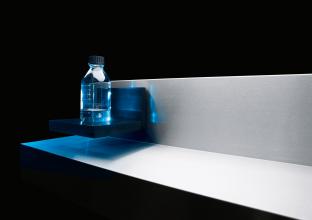

SupraSensor: measuring and weighing without contact

One of the many possibilities is shown by the SupraSensor, an exhibit presented by Festo at the Achema 2022 trade fair. It demonstrates the function of a contactless balance, which could be used for example on safety workbenches in biological or chemical analytics. This concept allows various physical quantities, such as weight, density, viscosity or temperature, to be measured using a force-based measuring system.

Possibility of application in laboratory environment

The technology carrier is attracting great interest among users. One application example would be a protected workstation for production or the laboratory environment, in which the SupraSensor is integrated as a non-contact scale. Maximum operator protection and good cleanability are very important here. With the floating weighing pan, both requirements can be implemented very well, since the complete technology is protected and not contaminated.

Easy-to-clean

“In a laboratory environment, workplace surfaces remain clear of apparatus and can therefore be effectively and easily cleaned, since everything except the carrier for the item to be weighed can be screened from the surroundings,” explains Michael Schöttner, Head of SupraMotion projects at Festo. “Only the weighing pan carrying the item hovers over the table top – without the danger of cross-contamination via the workplace surface or tools.” Both can be decoupled from the surroundings without vibration.

If the pan is not needed, it can be removed and the entire working space of the sterile workbench becomes available. This is made possible by the special property of superconductors, which can fix magnets suspended at a certain distance when cooled to a certain temperature. The exhibit thus impressively demonstrates how separate workspaces and work equipment, including sensors, can be coupled together without contact.

Applications in medical technology

In addition to purely measuring and weighing, this technology offers numerous further possibilities such as analytical determination of density or viscosity, precise metering or the surveillance of reactive or biological processes. “The possibility of handling objects without contact and thus completely free of contamination is of great interest above all in medical technology. Since no friction arises, measurements are not falsified and are absolutely precise,” says Dr Frank Jacob, Head of the LifeTech Business Unit at Festo. The technology is very robust and stable both spatially and temporally: the material-intrinsic levitation function does not require any control technology and remains in place for a long time even if the power supply is interrupted.

Superconductors: materials with special characteristics

Superconductors are materials that can store the field of a permanent magnet at a defined distance below a certain temperature. With this effect, objects can be held in position and moved free of contact. The levitation gap remains stable even beyond walls. Thanks to its restoring forces, the superconductive magnetic bearing components autonomously return to their stored positions, even if one of them is temporarily removed – without the need for external regulation technology. The technology is very robust and stable in terms of both space and time: the levitation function, which is intrinsic to the material, does not require any regulation technology and remains stable over long periods, even if the power supply is interrupted.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.