From the blank to the bottle under high pressure

Thanks to high-pressure pneumatics, stretch blow moulding machines achieve an output per blow moulding station of between 1,000 and nearly 3,000 PET bottles per hour. The key to this success is precise control using valves and valve blocks and the proper compressed air preparation. These are supplied by Festo, along with global services, from design engineering tools to operation. At drinktec in Munich in September 2022, innovative digitalisation solutions for monitoring and smart components in high-pressure applications will be on show for the first time.

For over ten years, the global player in automation technology has been developing a comprehensive range of components for high-pressure pneumatics up to 40 bar for manufacturing PET bottles using blow moulding for linear and rotary machines. The development engineers at the company’s headquarters in Esslingen use their own high-pressure laboratory where the pneumatic products are qualified. The products are manufactured and tested in the Festo Scharnhausen Technology Plant, located near Esslingen, in accordance with the Pressure Equipment Directive. You can rest assured that you get all the appropriate approvals and the quality feature “Made in Germany”.

Machine learning for monitoring

At the moment, the Festo developers are working on digitalised high-pressure applications for monitoring and other smart components. The Festo AX machine learning software plays its part, too, since it monitors and analyses machine data. It also helps to optimise production processes and save valuable resources, ensuring greater sustainability and energy efficiency.

The data collected during monitoring can be analysed via dashboards and the condition of individual valves or, depending on the scope, even entire systems can be tracked. It is not just machine conditions that can be monitored; it also makes it possible to carry out predictive maintenance.

Customised solutions for high-pressure pneumatics

The comprehensive standard range of high-pressure pneumatic products with air preparation for small to large flow rates, with modular service unit components, regulators, filters, switch-on and switch-off valves and proportional valves leaves nothing to be desired when it comes to the development of stretch blow moulding machines. In addition to the standard product range, Festo develops customised service units and valve blocks for individual machine solutions.

As a full-service provider of pneumatic and electric automation, Festo can also set the entire production line in motion, from pre-forming to palletising. Depending on the application area, Festo produces valve terminals, control cabinets, drives, control blocks, high-pressure pneumatic products or system solutions.

At the end of 2021, Festo received the “Customer Centric” award from the Sidel Group. One of the most important manufacturers of beverage filling systems thus acknowledged the tireless commitment of the Festo workers in Sales, Production, Supply Chain and Development in ensuring delivery capability.

Images and captions:

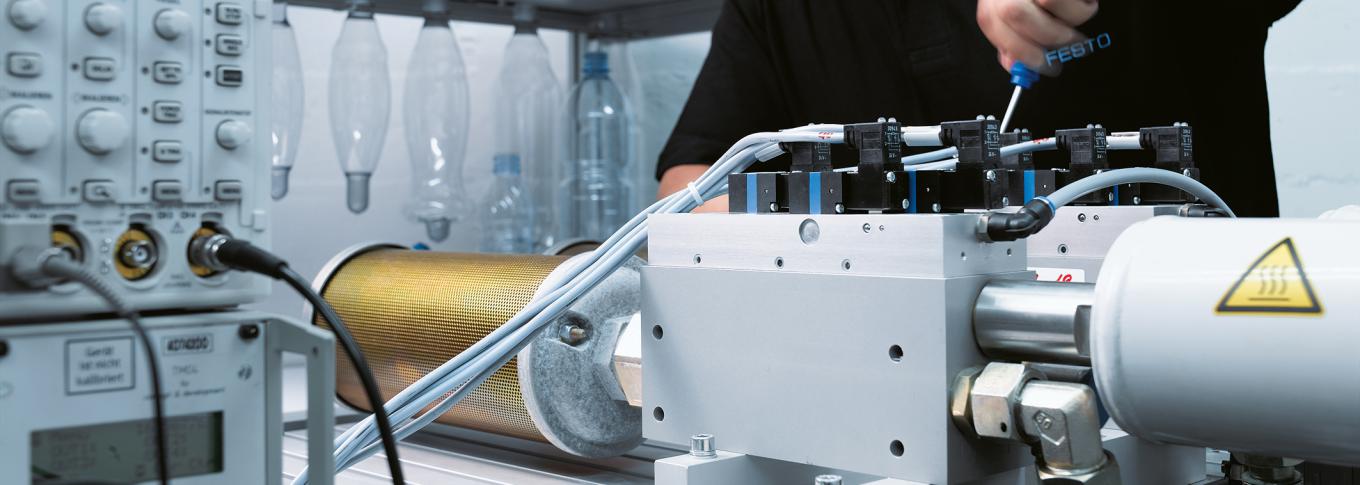

High-pressure lab:

High-pressure laboratory at Festo: here, components of high-pressure pneumatics up to 40 bar are developed for the production of PET bottles in the stretch blow moulding process for linear and rotary machines (Image: Festo SE & Co. KG))

High-pressure valve block:

Precise control for high-pressure pneumatics – with a valve block from Festo (Image: Festo SE & Co. KG)

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.