The right handling system in a matter of minutes

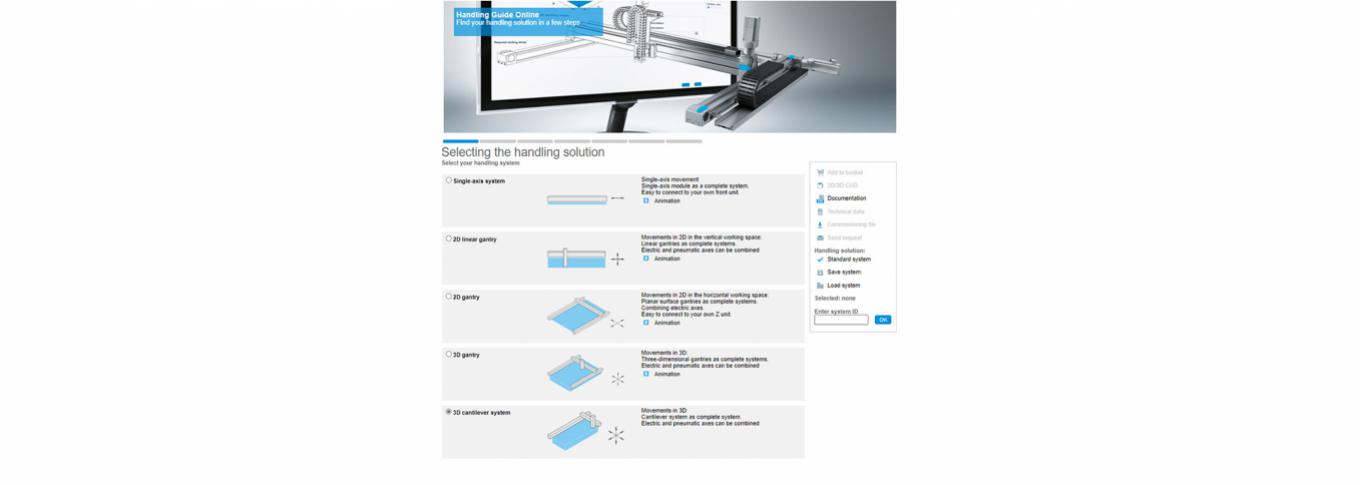

With the Handling Guide Online, design engineers can create the right ready-to-install handling system from Festo in record time, whether for a 2D linear and planar surface gantry, a 3D gantry or a new 3D cantilever system. Not only can they now plan extremely compact or extremely dynamic Cartesian robots using the intuitive configuration and ordering software, but they also benefit from the circuit diagram service from Eplan and commissioning files.

In the Handling Guide Online from Festo design and project engineers have a smart and intuitive tool to configure and create new system solutions without disrupting the value chain. This is thanks to the integration of the configuration and ordering platform into the Festo online product catalogue. So planners are just a few mouse clicks away from the right standard handling system, including CAD model. The individual steps including RFQ, layout, quotation and CAD design, which previously took 10 to 15 days, can now be done in just a matter of minutes using the Handling Guide Online.

Complete value chain

The Handling Guide Online cuts assembly and delivery times from nearly two months to just a few weeks. New standard products are also shortening parameterisation and commissioning times. Machine and system builders are thus able to reduce their time to market for integrated handling systems by around 70%. Thanks to this engineering tool, design engineers have more time and space for creativity when planning and project engineering their companies' core areas of technological expertise.

A single click transmits the order to Festo. The handling experts from Festo deliver a ready-to-install system, including all user documentation in accordance with the EU Machinery Directive, directly to the machine or plant in no time at all.

Extensive new hardware expansions

Where compact dimensions are required in assembly systems, test and inspection systems, in small parts handling, in the electronics industry or in desktop applications, the new Cartesian robots YXC...-B based on the spindle and toothed belt axes of type ELGC and the mini slides EGSC from Festo demonstrate their advantages in terms of space and cost efficiency.

In addition to linear, planar surface and 3D gantries, 3D cantilever systems with low-interference contours and working space accessible from 3 sides can now also be configured.

Enhancements to the drive systems, consisting of the CMMT-AS servo drive and EMMT-AS servo motor from Festo, enable seamless connectivity in hardware and software.

Circuit diagram service from Eplan – Schematic Solution

Why use up the time of an engineer to do less than productive tasks when there is a service to do this for them? In fact, creating an Eplan project can take several hours and, depending on the complexity, is prone to errors. Schematic Solution automates many of the process steps and therefore frees up time for creative tasks and also documents projects without any errors. The individual electrical circuit and pneumatic diagrams can be purchased as an Eplan project and as a PDF via Schematic Solution in the Festo App World.

Data is managed consistently throughout the entire process, resulting in an Eplan project with a unique system ID for each individual handling system. Error-free documentation for the configured handling system with a mechatronic image of the configured motors and drives such as EMMT-AS and CMMT-AS is generated at the touch of a button. Thanks to the integration of the circuit diagram service, configuring handling systems is not only more reliable, but also less expensive because valuable time can be used for creative activities.

Efficient commissioning – Festo Automation Suite

Festo now offers commissioning files for fast commissioning. The files are custom created on the basis of user input and the calculated system and can be loaded directly via Festo Automation Suite into the motor controller. The commissioning file contains a set of values specifically for the handling system, consisting of axis dimensions, motor characteristics, feed constants and dynamic data.

A special feature is that the controller settings are automatically calculated on the basis of the payload, the dead weight and the system dynamics entered by the user.

Breakthrough in digitalisation

With the Handling Guide Online, Festo is driving digitalisation forward and supporting its customers to enter the age of Industry 4.0. Automation expert Festo is combining its extensive knowledge of industrial applications with the latest developments in information technology to realise online applications for industrial automation practice. Festo is also using digital communication to support its customers throughout the Digital Customer Journey. This digital journey guides customers reliably and comprehensively through the Festo portfolio, from information procurement and configuration through ordering and delivery to commissioning and maintenance or even to the technical training offered by Festo Didactic.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.