Festo gives the future of safe automation a hand

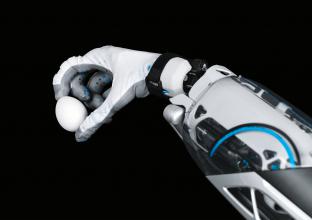

BionicSoftHand 2.0 uses a combination of compact valve technology, sensors, electronics and mechanical components to emulate the movements of a human hand.

Industrial change has accelerated, demanding a new level of interaction between people, machines and data. Within its Bionic Learning Network, Festo has been studying and developing safe automation systems to relieve people of monotonous or hazardous tasks. The BionicMobileAssistant is a prototype robot system that deploys artificial intelligence to move independently, identifying and gripping objects and adaptively working with humans.

The entire system has been developed in collaboration with ETH Zurich. It has a modular design consisting of three subsystems: a mobile robot, an electric robotic arm and a pneumatic gripper – the BionicSoftHand 2.0 – an earlier version of which was first presented by Festo in 2019. It uses a combination of compact valve technology, sensors, electronics and mechanical components integrated in the tightest of spaces in order to emulate the movements of a human hand.

BionicSoftHand 2.0 wears a tactile glove with force sensors on the fingertips, the palm and the outer sides of the robot hand. This allows it to sense the nature of the item to be gripped, and to adapt its gripping force accordingly – just as the human hand does. Thanks to a 3D-printed wrist with two degrees of freedom, the hand can also move both back and forth as well as to the left and to the right. This means that gripping smaller objects is now possible. In addition, the hand has a depth camera on the inside of the wrist so it can visually detect the objects to be gripped – even if these are partially obscured. The information is processed by a neural network, which has been trained in advance with the aid of data augmentation. Once the hand has been correctly trained, it uses the intelligence gathered to assess objects.

The system would be perfect for differentiating good product from bad product, or for use as a personal assistant: for example as a service robot helping in assembly or assisting workers in carrying out ergonomically monotonous tasks. It could also be used in environments where people cannot work because of hazards or restricted accessibility. This includes maintenance or repair work, data measurements or visual inspections. It is also possible to imagine mobile robots carrying out tasks in areas where there is an increased risk of infection: delivering medicines to hospital patients, supporting the delivery of care in old people’s homes, or waving ultralight sterilising wands within wards.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.