Multiple functions in a small workspace

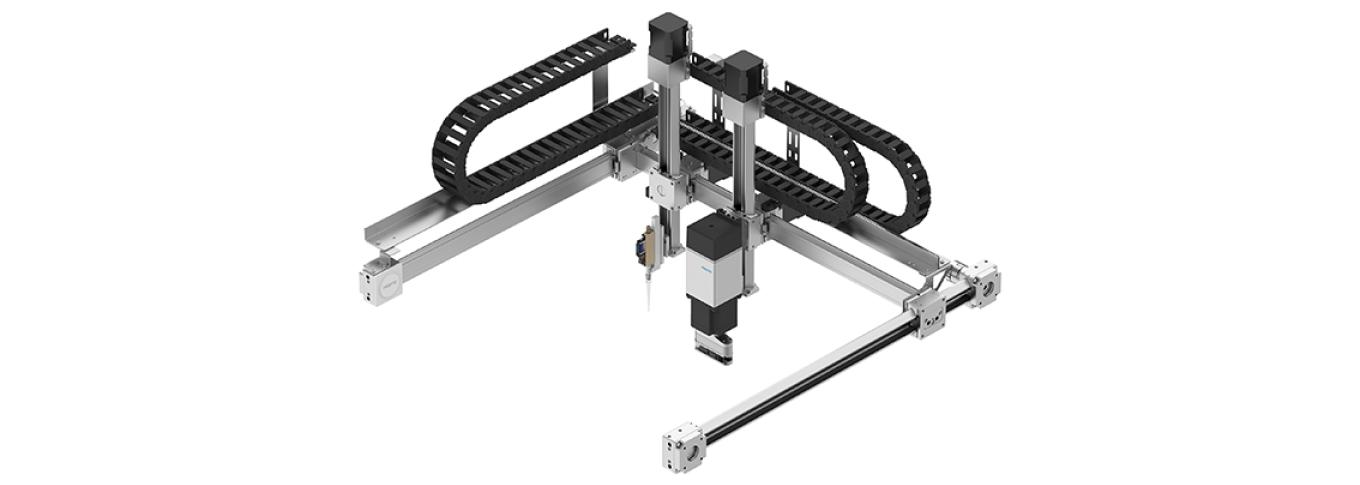

Opening sample vessels and pipetting liquid samples in the same workspace saves space in laboratories. This can now be achieved with the three-dimensional gantry EXCL from Festo, which has a small footprint for table-top devices and PCB-based motion control.

The three-dimensional gantry EXCL reduces purchasing, design and assembly costs for automated sample handling and liquid dosing in laboratory equipment. It is therefore ideal for analytical processes where sample vessels are to be opened and liquid samples need to be pipetted in the same workspace. The optional second Z-axis even enables two front ends, such as the rotary gripper module EHMD or the pipetting head DHOE, to be moved independently of each other.

Cooperation saves time and costs

The three-dimensional gantry is perfectly suitable for desktop systems without a control cabinet, applications with low requirements for dynamic movement, such as preparing or analyzing samples using the liquid handling solutions for dispensing and pipetting from Festo. It forms an ideal unit for life sciences and laboratory automation environments. Many device manufacturers benefit from a quicker time to market by working with Festo early on in the development process, so that 3D gantries such as the EXCL can be included in the system design from the beginning. This saves you time, effort and risk compared to developing and assembling gantries in-house. Regional service centers from Festo around the world are also available to offer you support with the 3D gantry EXCL.

The three-dimensional gantry with stepper motors and optional motion controller can be easily integrated in desktop systems. The maintenance-free system is tested and documented. The motion controller of the EXCL can be addressed via G-code. This means that the higher-level controller can simply send the target coordinates for the front ends, so that no complex configurations are necessary. In addition, the motion controller panel can be easily mounted in the unit and does not require a control cabinet. Festo supplies the EXCL as a kit with pre-assembled axes, ensuring quick and easy assembly.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.