Multiple functions in a small workspace

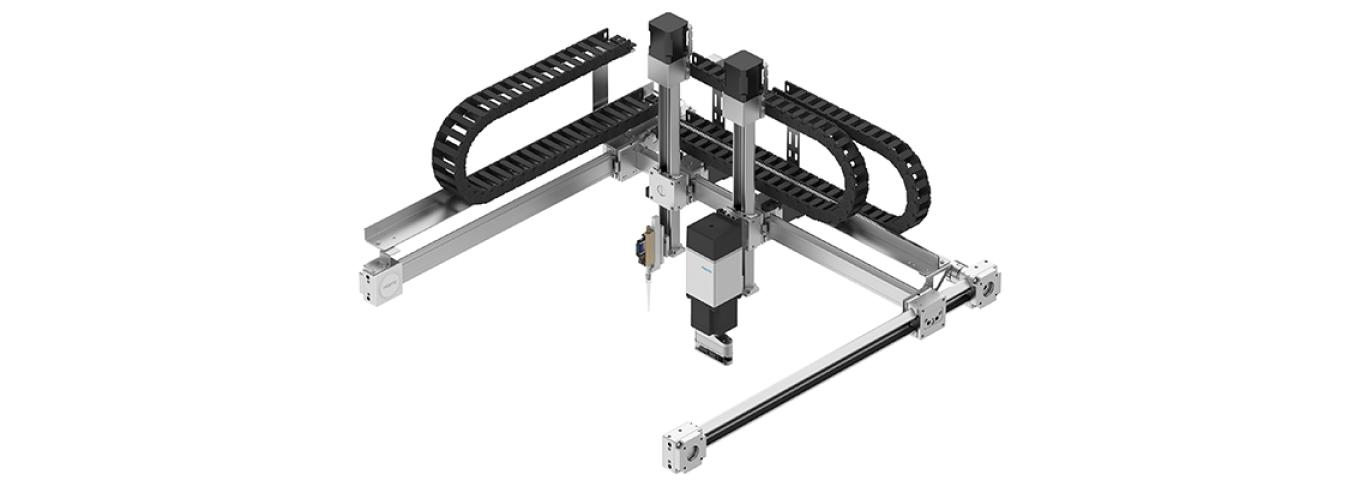

Opening sample vessels and pipetting liquid samples in the same workspace saves space in laboratories. This can now be achieved with the three-dimensional gantry EXCL from Festo, which has a small footprint for table-top devices and PCB-based motion control.

The three-dimensional gantry EXCL reduces purchasing, design and assembly costs for automated sample handling and liquid dosing in laboratory equipment. It is therefore ideal for analytical processes where sample vessels are to be opened and liquid samples need to be pipetted in the same workspace. The optional second Z-axis even enables two front ends, such as the rotary gripper module EHMD or the pipetting head DHOE, to be moved independently of each other.

Cooperation saves time and costs

The three-dimensional gantry is perfectly suitable for desktop systems without a control cabinet, applications with low requirements for dynamic movement, such as preparing or analyzing samples using the liquid handling solutions for dispensing and pipetting from Festo. It forms an ideal unit for life sciences and laboratory automation environments. Many device manufacturers benefit from a quicker time to market by working with Festo early on in the development process, so that 3D gantries such as the EXCL can be included in the system design from the beginning. This saves you time, effort and risk compared to developing and assembling gantries in-house. Regional service centers from Festo around the world are also available to offer you support with the 3D gantry EXCL.

The three-dimensional gantry with stepper motors and optional motion controller can be easily integrated in desktop systems. The maintenance-free system is tested and documented. The motion controller of the EXCL can be addressed via G-code. This means that the higher-level controller can simply send the target coordinates for the front ends, so that no complex configurations are necessary. In addition, the motion controller panel can be easily mounted in the unit and does not require a control cabinet. Festo supplies the EXCL as a kit with pre-assembled axes, ensuring quick and easy assembly.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。