Added value from data reduces downtime and waste

On the shopfloor, machines not only deliver products, but also large amounts of data that are converted into information using artificial intelligence in such a way that they show humans specific optimization potential . Initial successes are visible: in hundreds of customer applications, solutions from the Festo AX Industrial Intelligence portfolio have reduced unplanned downtimes by up to 25 % and cut waste by 20 %.

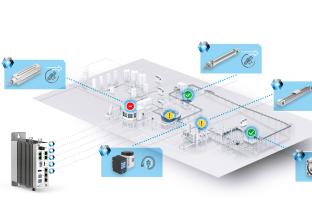

Standardized, simple and immediately ready for operation: With the Festo AX Industrial Apps, components can be optimized in terms of transparency, availability, performance and quality. If the technical requirements are met, retrofitting is also possible. Two Festo AX Industrial Apps are already available, and two more will be available in the coming months: Here, the AX Data Access app creates MQTT data access to Festo components, also available for Siemens Industrial Edge (IE). AX Motion Insights Pneumatic detects faults in pneumatic drives. AX Motion Insights Electric will soon be added to the portfolio to detect faults in electric drives. The fourth app in the group, AX Energy Insights, reports deviations in energy consumption.

Security and time savings

Together, the apps offer many advantages such as security, as they are easy to put into operation without any AI knowledge. They also save time, as system operators get a quick overview of the data thanks to intuitive dashboards and reports. They are compatible in the long term and ensure simple data integration into third-party systems. They are also fully digital and offer a direct connection to AX Smartenance for digital maintenance management. This means that a relevant component can be repaired or replaced at an early stage as part of planned maintenance and unplanned downtimes can be avoided.

Solution packages are always created when many similar requests have been processed and the expertise for these usually complex solutions is available. Festo has created AI solutions for a wide range of requirements that can be quickly adapted for machines and systems. Festo AX Solutions offer benefits such as increasing the efficiency of production processes, for example in packaging, riveting, gluing or welding in automotive body construction. They reduce downtime and energy costs. They increase quality and productivity (OEE).

From error detection to error correction

Festo AX Smartenance is a manufacturer-independent software that makes maintenance and servicing of systems more efficient and reduces costs - fast, paperless, consistent. AX Smartenance is already being used successfully by many different customers. Now powerful functions are being added: the SAP S4-HANA interface synchronizes machines and fault management from SAP systems with AX Smartenance. This solution with SAP is very easy to use. Spare parts management assigns spare parts to machines and incidents. This means that all important information is available on site and mobile. With the new service module, all Festo components can be found easily, intuitively and quickly - with associated documents, spare parts and information. Manual documentation is no longer necessary and time-consuming searching is a thing of the past. The service module is integrated into AX Smartenance and can be used immediately without logging in.

Industrial transformation

Entire branches of industry and sectors are undergoing profound change. This is having a massive impact on production environments, processes and supply chains. The drivers of this change are technological change, digitalization and the need to reduce CO2 emissions. With digitalization and artificial intelligence, Festo is opening up innovative solutions for the factory of the future, with greater efficiency and sustainability through to a climate-neutral circular economy.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.