New PROFINET bus interfaces from Festo

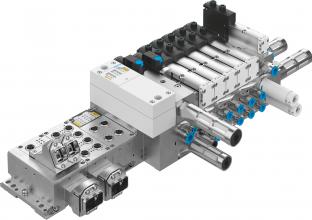

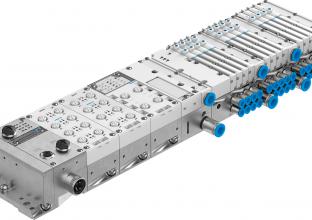

Festo has upgraded its PROFINET bus interfaces for the CPX automation platform. The new generation has four new key features based on the new PROFINET controllers and software, with the “S2 system redundancy” being the most important one.

In addition to the S2 system redundancy, the interfaces provide three further equipment features: MRPD for uninterrupted ring redundancy, voltage monitoring and NTP time synchronisation.

S2 system redundancy

The S2 system redundancy guarantees uninterrupted processes. If a CPU error occurs, the process continues to run via the redundantly installed CPU. The CPU switchover takes place automatically. The S2 system redundancy can be combined with either MRP or MRPD redundancy and its ring topology. It also opens up opportunities for the CPX automation platform with the PROFINET bus interfaces in the process industry when Siemens PCS, S7 controllers and ABB control systems are used.

MRPD approach for media redundancy with planned duplication

MRPD and MRP prevent malfunctions or loss of communication caused by a cable or device defect during the transfer of cyclical data. The new 40 series bus interfaces support both protocols. This requires a ring topology where the data is transmitted in both directions. The first data package arriving at the receiver is evaluated, later ones are discarded.

Integrated supply and load voltage monitoring

The integrated monitor detects voltage losses when the bus subscribers are linked. These voltage losses are dependent on cable length, current intensity and the connectors used. The bus interfaces measure the 24 V power supply and the load voltage. The measurement data are indicators and can be displayed in the web server as device information.

Network Time Protocol (NTP)

The bus interfaces are time-synchronised with the NTP server. The connection delay and the local time delay are calculated. An integrated SNTP client has full NTP compatibility with an accuracy of ±0.5s.

With the PROFINET bus interfaces for the CPX automation platform from Festo, assets and diagnostics as well as process and parameter data can be visualised via a web page, thus reducing engineering costs. In addition, IT services help to reduce downtimes. The integrated diagnostic concept and valve diagnostics increase machine availability. The high protection rating to IP67 enables direct machine mounting.

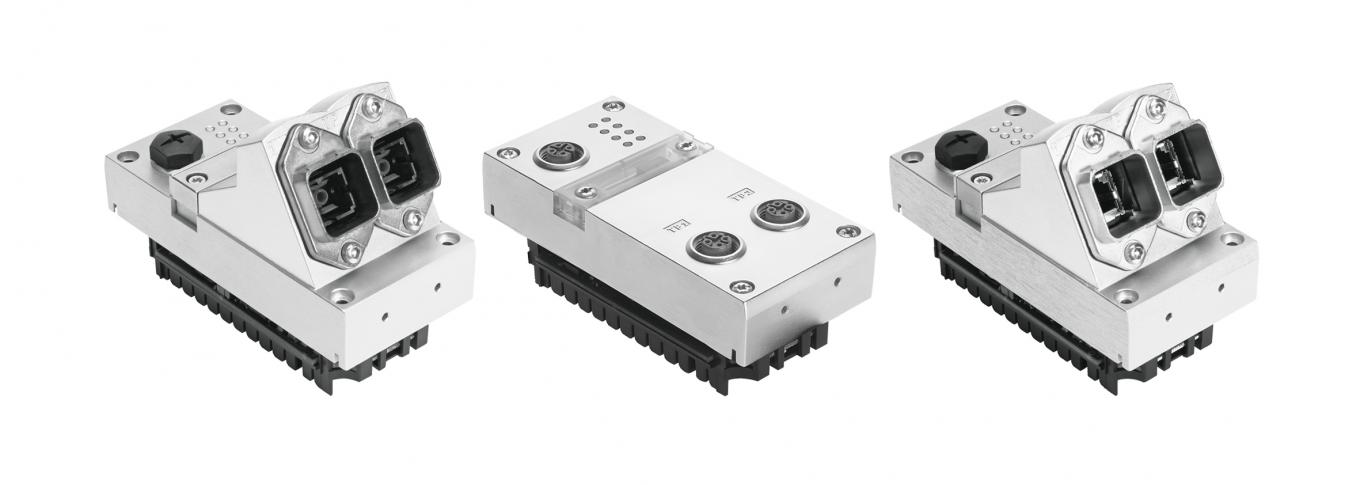

Fast replacement possible

During the development process, Festo made one-to-one compatibility between the new 40 series nodes and their predecessors a priority. This enables users to replace old FB34 bus interfaces in existing installations with new FB44 ones, for example, without having to make any changes to the existing configuration. The existing data cables and connectors can continue to be used and even the old GDSML files are retained.

All that is needed to change the bus interfaces is to remove the old nodes, fit the new ones and fasten them in place. This means that an existing CPX automation platform or valve terminal with bus interface can be easily integrated into a PROFINET upgrade.

PROFINET is the most widely used Industrial Ethernet protocol worldwide with a market share of 29%. At Festo, PROFINET is the highest selling Industrial Ethernet protocol.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。