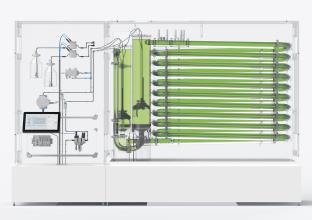

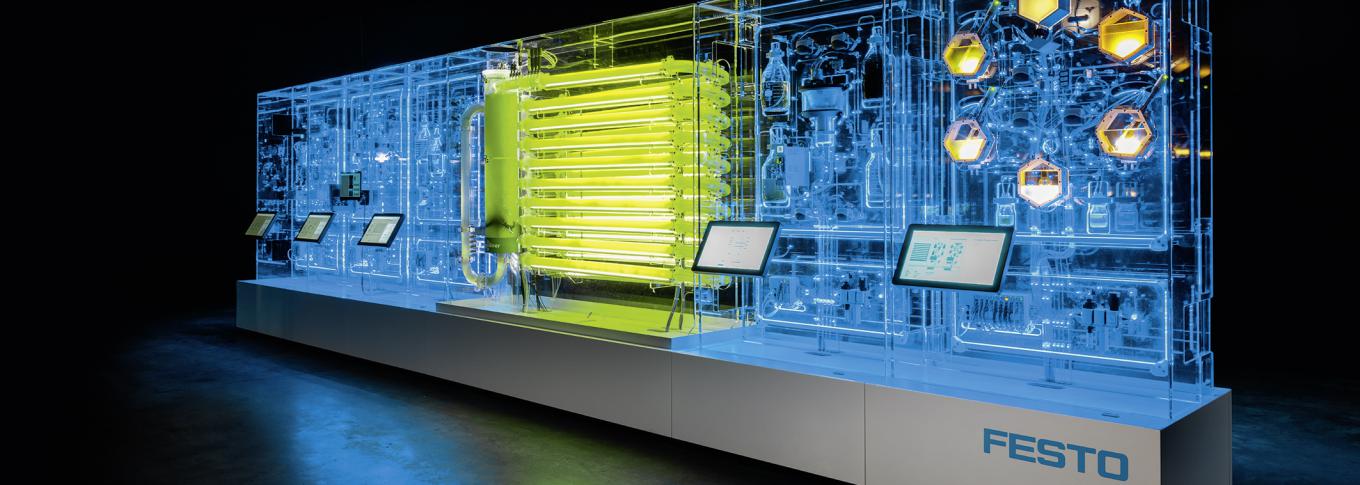

Cultivation of biomass on an industrial scale

At the Hannover Messe 2023, Festo is presenting the next step on the road to the industrialisation of biological transformation: BionicCellFactory. With automation technology from Festo, biomass can be cultivated on a large scale in a highly efficient, resource-conserving way. Everything that we currently produce from crude oil creating immense CO2 emissions can also be obtained sustainably from algae. With the BionicCellFactory, Festo is demonstrating a holistic bioprocess – from the optimised cultivation of the algae with continuous monitoring and analysis through to harvesting and the further processing and refinement of the various components. The biomass obtained can be used in the chemical, food or pharmaceutical industries.

Climate and resource protection are two of the great challenges of our time. How can we extract CO2 from the atmosphere and actively contribute to climate protection? How can we reduce our material consumption, recycle more materials and at the same time access alternative raw materials? At Festo, we have been dealing with these questions for some time and are breaking new ground: ‘We are transfer our expertise of automation technology to biological processes. Here, too, nature is our great paragon. It teaches us about resource efficiency, because in nature there is no waste or wastage. We scale and accelerate solutions from the laboratory format and bring them to industrial application through the interplay of biological and technical processes,’ explains Dr Elias Knubben, Vice President Corporate Research and Innovation.

The cell as a factory

Living cells are the smallest factories in the world. Algae’s chloroplast cells photosynthesise to convert sunlight, carbon dioxide and water into oxygen and chemical energy sources – or valuable organic matter.

Optimised growth conditions thanks to automation

With our automation technology, biomass can be cultivated in a closed cycle in a highly efficient, resource-saving way and on a large scale. Everything that we currently produce from crude oil creating immense CO2 emissions can also be obtained sustainably from algae. They are small planet protectors because they absorb ten times more CO2 than land plants. This value can be increased by a factor of ten through automated cultivation in bioreactors. The biomass obtained can be used in the chemical, food or pharmaceutical industries.

Holistic process all the way up to harvesting and refinement

With the PhotoBionicCell project, Festo presented its first bioreactor for the automated cultivation of algae in 2022. This year, the interdisciplinary bionics team is going even further. With the BionicCellFactory, it is demonstrating a holistic bioprocess – from the optimised cultivation of the algae on a large scale with continuous monitoring and analysis through to harvesting and the further processing and refinement of the various components. In contrast to chemical processes, without high temperatures, high pressures and toxins.

Production systems of the future

As a model factory, the BionicCellFactory is the universal blueprint for holistic production systems of the future. With the help of the Festo automation technology, it can be scaled to any size. In order to meet future demand for renewable raw materials, bioreactors with a capacity of several thousand litres are needed. Expertise in process automation is required to ensure that the plants can reliably produce the desired quantities of biomass.

Biological transformation portfolio

Together with its customers, Festo develops intelligent control cabinet solutions for bioreactors and continues to expand its portfolio. The automation specialist ensures stable and precise process control with maximum productivity. This includes optimised fumigation and feeding strategies, control algorithms, soft sensors for real-time biomass determination, and system concepts for bio-based production processes.

Festo will also support plant operators with remote diagnostics, maintenance and control via the cloud. Robust value creation processes and easy operation of the system modules will be important if a large number of modular production units for the extraction of raw materials and carbon fixation are to be built and operated around the world in the future.

New job profiles for new technologies

However, highly qualified technical staff and biotechnologists are not available everywhere. To this end, Festo Didactic is already analysing the new knowledge requirements in order to define interdisciplinary links and establish innovative apprenticeships, degree programs and additional qualifications in the fields of biomechatronics, biointelligence and sustainability.

Further information about the BionicCellFactory: www.festo.com/bioniccellfactory

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。