Recycling rare minerals economically

According to estimates, by 2025 some 600,000 tons of used batteries from electric passenger cars need to be recycled. Since batteries are energy storage devices made from valuable raw materials, this inevitably raises the question of sustainability. Festo therefore offers modular automation concepts not only for cell producing, assembling battery modules and packs, and platform integration, but also for disassembling and recycling or separating the materials.

After around 1500 charging and discharging cycles, i.e. after about 160,000 kilometers in 8 to 10 years, the batteries of electric cars are hardly profitable anymore. The reason: compared to the new system, the reduced charging capacity of the batteries considerably shortens the range. However, a residual capacity of around 80% gives the batteries a second life, for example as part of a battery farm. With increasing automation of dismantling, the recycling process is becoming more flexible and dynamic, which also means that material is available for recycling more quickly. Festo is driving this development forward with a view to its vision of a sustainable circular economy.

In addition, proper disposal has already become mandatory in many states and countries. In Europe, the EU Battery Directive requires manufacturers to recycle or return batteries. Recycling is also mandatory in the US state of California.

Automated recycling

However, before used vehicle batteries are recycled, they are removed from the vehicle and used in so-called "battery farms" or stationary storage systems, for example. At the end of a battery's life, however, it must be professionally recycled. The first step is to mechanically dismantle the packs into modules, battery cells and other components - until now a manual, difficult and time-consuming task. Festo already offers modular automation concepts that speed up and simplify this process.

The next step is to recover valuable lithium, cobalt, manganese and nickel from used batteries and reuse them for the production of new batteries. Automated recycling processes enable these rare minerals to be reused economically and cleanly. Festo has the right recipes for this.

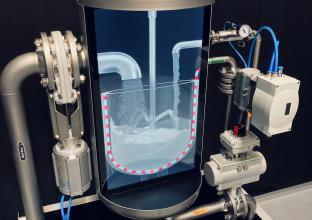

Most batteries in electric vehicles are lithium-ion batteries. Their proper disposal is important in order to avoid risks to people and the environment. New concepts for recycling and recovering raw materials support the industry in this. Various combinations of mechanical, pyrometallurgical and hydrometallurgical processes are used to recycle battery materials. The hydrometallurgical recycling process, for example, is a chemical precipitation method using acid. Rare minerals are extracted from the black mass as metal salt. These minerals are supplied to battery manufacturers who reuse them for the production of new batteries.

Dismantling systems for modules and packs

Special factory systems are already being planned for these tasks. Festo has already developed and presented its first mechanical modular disassembly system for battery modules and packs. Both handling and gripper systems as well as proven components from Festo's pneumatic and electric automation portfolio are used.

Festo is also already looking to the future of electromobility: It is involved in research into manufacturing concepts for new types of solid-state batteries. Experts predict that these even more powerful storage systems will replace the current lithium-ion batteries in the coming years.

Requirements of the new giga-factories for production sites

Large areas, good transport connections, low development costs and a secure and sustainable energy supply are important prerequisites that are usually found far away from urban centers. An important aspect is having enough skilled personnel. The conversion to electromobility will not only create new factories, but also new tasks, fields of activity and job profiles. Employees need to be educated and trained for this.

Qualification necessary

Festo Didactic provides targeted training programs. Here, employees receive the know-how that is needed in highly automated production. The offer includes practical hands-on training in the plants, the establishment of in-house learning factories and digital learning content that can be accessed on the Festo Learning Experience (Festo LX) at any time and from any location - including on the topic of sustainability.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。