From consistent data to lifelong added value

From digital twins to efficient circuit diagrams, from design tools to maximum energy savings – Festo supports its customers holistically and in every phase of their value creation process. This extends to the circular economy and the product carbon footprint, but also to lifelong learning with digital training tools for both trainees and long-term employees.

Automation engineers can realize great savings potential right from the start of a machine's design. With appropriate sizing tools, digital twins and efficient circuit diagrams, savings of up to 80% can be achieved by correctly dimensioning the drives, planning downstream AI monitoring of the machine or importing data via digital twins. Design tools such as Electric Motion Sizing for optimal drive and mechanical dimensioning, Handling Guide Online for simple multi-axis cartesian engineering or FluidDraw for electrical and pneumatic circuit diagrams are just a few examples of the many calculation tools that Festo uses to make planning and design easier for its customers.

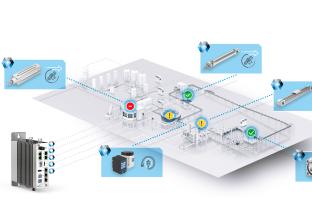

Savings potential through digitalization and AI in the ongoing production process

The digital maintenance tool Festo AX Smartenance and the Festo AX Industrial Intelligence software enable networked production monitored by AI. This empowers customers to save up to 50% of resources through more efficient processes together with reducing unplanned downtimes by up to 25%.

Festo AX Smartenance is a CMMS (Computerized Maintenance Management System) software and combines maintenance, servicing, spare parts management and machine logbook in one solution. The web application for maintenance or production managers and the mobile app for maintenance staff and machine operators ensures that all relevant information about a machine can be called up anytime and anywhere.

Avoiding unplanned downtimes, ensuring product quality and reducing energy costs – Festo AX Industrial Intelligence makes it all possible. "AI supports our customers in terms of solution design, energy consumption and preventive maintenance. Festo plays a leading role when it comes to AI in the industrial environment. These are skills that are based on years of expertise and inventiveness at Festo," explains Gerhard Borho, Member of the Management Board for IT and Digitalization at Festo.

New are pre-trained AI apps that can even be used by users without extensive AI expertise. This enables companies to record real-time data from production processes and analyze it with the help of AI.

The use of AI enables,

- predictive maintenance to reduce downtimes by up to 25%

- optimized product quality assurance (predictive quality) and thus reduces rejects by up to 20%

- The more efficient use of resources (predictive energy) by reducing leakages by up to 65%.

Integrating sustainability: smarter, greener industrial automation

The product carbon footprint (PCF) describes the effect the CO₂ consumption of the product has on the environment throughout its product lifecycle. A simple example: Festo offers repair kits for many products. Through these repairs 90% CO₂ can be saved throught the product lifecycle compared to buying a replacement part. All the data on Festo's products is available in Festo AX Smartenance. If you combine the circular economy with digitalization, all the data from design and operation can be used via an enriched digital twin.

Lifelong learning: a "must" in the age of digitalization

From tailor-made learning packages and digital platforms to complete training centers, Festo Didactic supports automation customers who want to equip their trainees and employees with new and essential digitalization skills. The experts combine their industry expertise with didactic know-how to ensure employability in high-tech industries. Festo LX, the interactive learning portal, is based on multimedia learning content that can be edited in modules and combined to create individual learning paths.

Tailored learning formats adapt to the learning situation. The so-called eLab courses are mainly used in vocational training in combination with physical learning systems. Pure e-learning courses, on the other hand, can be used without a learning system and accompany learners beyond the field of training and into continuing professional development.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。