Why it is important to optimally regulate pressure and flow

Efficiency, process stability and energy savings are key factors in modern production, especially in applications involving sensitive goods. Achieving this requires an intelligent control concept that precisely and flexibly regulates pressure and flow while minimizing energy consumption. With Controlled Pneumatics, Festo offers the perfect solution by combining proportional technology, sensor systems, and digital control.

Unlike conventional systems with fixed settings, Controlled Pneumatics continuously adjusts values in real time. The result is improved product quality, reduced compressed air consumption, and longer service life for components.

Stable processes

In practice, fluctuations in pressure and flow often lead to defective products. This is especially critical in industries such as automotive, medical technology, food, and packaging, where stable processes are essential to prevent rejects and costly rework. Inconsistent pressure across different production stations is a common issue and can cause cylinders to position components inaccurately or seals to be applied with incorrect force.

Proportional valves with closed-loop control can make a significant difference. They reliably maintain the pressure at the required level, regardless of load changes, fluctuating input pressure, or minor leaks. In practice, unstable processes often result in high reject rates. These can be drastically reduced with intelligent pressure and flow regulation.

Pushing the boundaries of pneumatics with Controlled Pneumatics

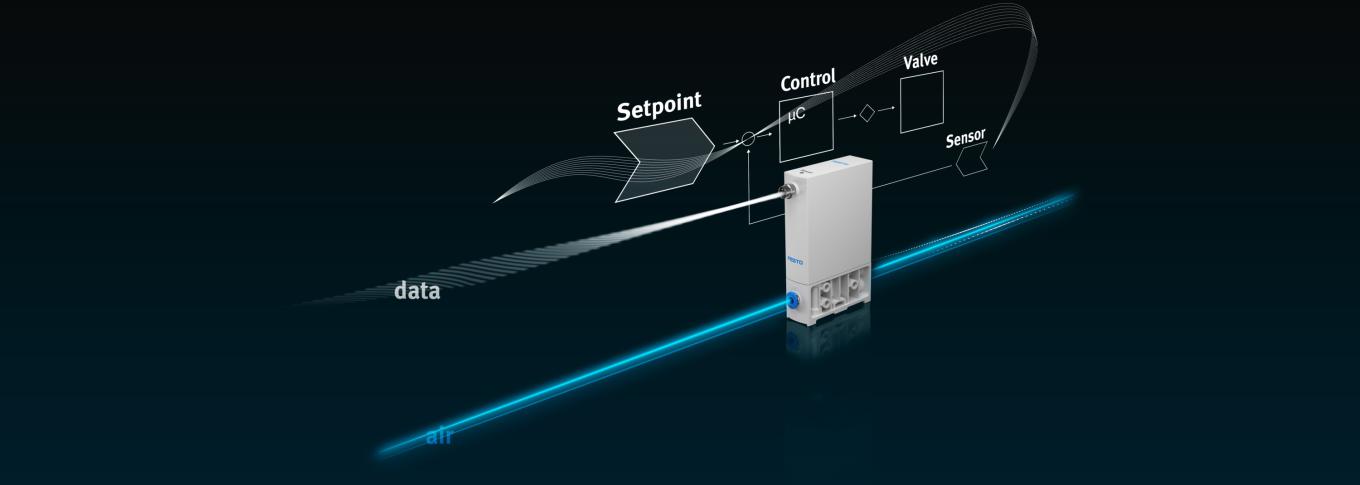

This innovative technology is opening up entirely new areas of application, especially in the precise regulation of pressure and flow. Controlled Pneumatics pushes beyond the boundaries of conventional pneumatics, resulting in solutions that are simpler, more reliable, faster, more precise, and more energy-efficient. Traditional standard pneumatics, by contrast, are typically used for straightforward applications such as point-to-point movements. Their simplicity, robustness, and cost-effectiveness continue to make them the ideal choice in many cases.

Controlled Pneumatics, however, are mechatronic pneumatic systems that incorporate advanced valve and communication technologies. These systems enable digital control combined with closed-loop regulation of sensor-based variables.

The new proportional-pressure regulator VEAB with IO-Link is an example of Controlled Pneumatics in action; it demonstrates just how precise and flexible modern pressure regulation can be. Based on cutting-edge piezo technology, the VEAB stands out with its exceptional control accuracy, virtually silent operation, and extensive diagnostic capabilities via IO-Link. Four customizable presets, intelligent switching functions, and easy plug-and-play commissioning make it the perfect solution for demanding applications such as web tension control, dosing processes, or force-controlled polishing.

Conclusion

For those looking to improve process reliability and product quality, precise and automated regulation of pressure and flow is essential. It not only minimizes errors but also ensures consistently high product quality, reduces downtime, and enhances overall system efficiency. For a deeper dive into the topic, a blog article from Festo offers valuable insights into how intelligent pressure and flow regulation can cut costs, stabilize processes, and prepare companies to meet future demands.

Link to blog article:

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。