SupraCube: Maximum flexibility in automation technology

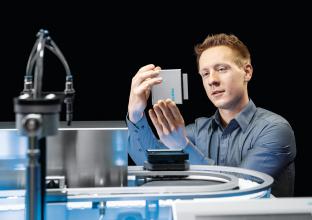

With the SupraCube, Festo is presenting for the first time a SupraMotion concept in which the superconductor unit can be separated from the electrical cooler and can operate autonomously for up to two hours. The compact technology allows contactless movement and handling of objects - ideal for industries with the highest requirements for cleaning and cleanliness, such as laboratory automation, biotechnology or semiconductor production.

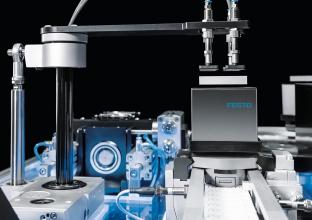

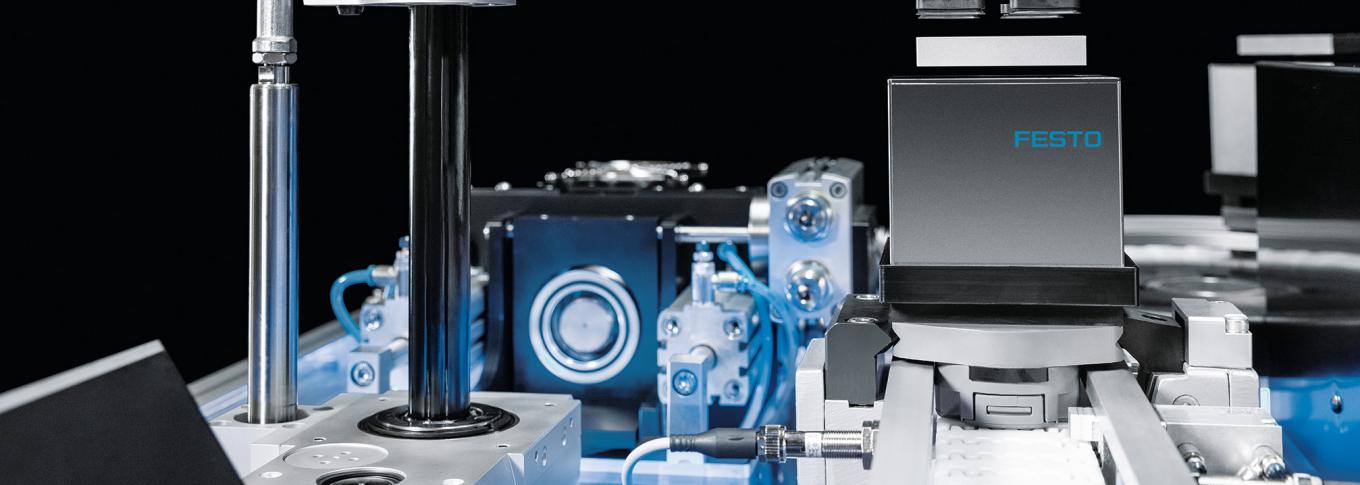

With the latest superconductor technology from Festo, magnetic levitation technology reaches a new level of flexibility. Previous solutions for magnetic levitation that were suitable for industrial use always suffered from their unwieldy dimensions. A disadvantage that often prevents applications in practice where compact and lightweight, yet reliable and robust solutions are required. With the SupraCube, Festo overcomes this obstacle and presents a solution that reduces magnetic levitation to the essentials: a passive magnetic base unit with a coupled levitation carrier above it.

The modular design of the system allows the superconductor to be cooled to -210°C before the cooling unit automatically switches off and the SupraCube decouples from it for up to two hours. Once cooled and disconnected from the cooler, the SupraCube is ready for use: mounted on the end of a robot arm, connected in parallel with other SupraCubes on a transport system, or for use in the safety lab next door. The stable floating connection between the magnetic carrier and the superconductor allows distances of ten millimetres and more – plenty of space for partitions enclosing clean or sterile work environments, for example.

Energy efficiency and more

While a SupraCube is in use, the docking station, which contains the electrical cryocooler and power supply, can sequentially power other modules to ensure seamless availability. During operation, the SupraCube is completely autonomous and neither consumes energy nor requires computing power for levitation control. Due to the sophisticated insulation, superconductivity is maintained even during downtimes of up to two hours. Because the SupraCube is completely passive, there are no interfering cables and no vibrations or electrical noise that could affect sensitive applications. Levitation is achieved without surfaces heating up, so heat-sensitive goods are not damaged and costly cooling is not necessary.

Superconducting levitation enables high-end technology

This non-contact, frictionless form of superconducting levitation offers an elegant and practical solution to some of the most challenging problems in high-tech industries, from semiconductors, batteries and biotechnology to pharmaceuticals, food, medical devices and laboratory automation. Reducing impurities of all kinds to an absolute minimum will help pave the way to the high-end technologies and products needed for a clean, healthy and sustainable future.

What are superconductors?

Superconductors are materials with unique magnetic properties. The superconductor used in SupraMotion applications can anchor the magnetic field of a permanent magnet inside it, creating a strong but invisible coupling that keeps the magnet and superconductor at a fixed and defined distance from each other - even through walls, in liquids or in a vacuum. As long as it remains below its transition temperature, the superconductor's magnetic memory stores the magnet's fingerprint and thus its position, even if the two are separated.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.