Precise and dynamic

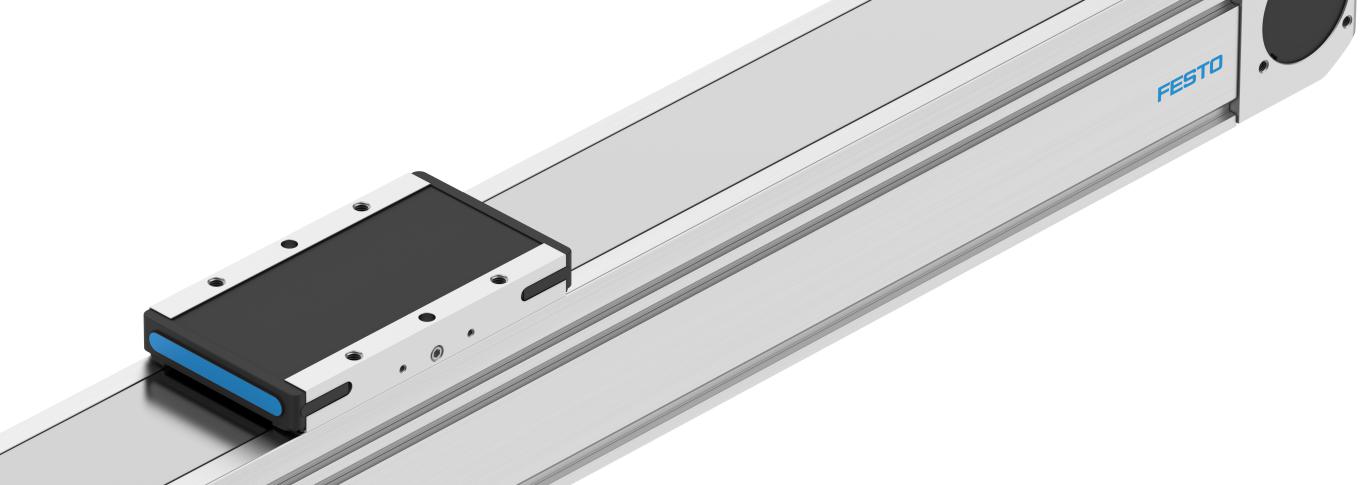

Innovative guide technology, high rigidity and guide load capacity for more load in the same installation space - these are the features of the new ELGD axis family from Festo. In addition, powerful drive elements offer high feed forces and accelerations for shorter cycle times, a long service life and less downtime. A stainless steel cover strip is friction-free on the outside and does not allow any particles to form there. This makes the drives in the axis family ideal for use in cleanrooms.

Thanks to these properties, the ELGD axle family with ELGD-BS spindle drive and ELGD-TB toothed belt drive is predestined for future-oriented industries such as renewable energies, the production of electric vehicles, the manufacture of batteries and the semiconductor industry. The ELGD axes are among the most rigid axes on the market. Using the example of a dispensing station, the specially developed guide concept enables the dispensing head to be moved precisely and dynamically. Attachments of up to 20 kg on the Y-axis are possible.

Innovative stainless steel cover strip solution

The non-abrasive properties and clean surface protect workpieces from particles. This means that they can even be used in clean rooms. Conversely, less dirt penetrates the axles, making them suitable for use in harsh environmental conditions.

When used in cantilever systems and pick-and-place solutions for handling small parts, the ELGD axes excel with short cycle times, high precision and repeat accuracy. In handling systems for top loaders, users appreciate the cost-performance ratio and the high travel speed, especially for long strokes. In 3D printing and additive manufacturing, it is crucial that the axes perform virtually vibration-free and very dynamic movements and are resistant to harsh environmental conditions.

The ELGD-BS and ELGD-BS-WD spindle axes offer a maximum stroke of up to 2.5 meters with their durable and high-precision recirculating ball screw. The motor position can be selected as axial or parallel. The ELGD-TB and ELGD-TB-WD toothed belt axes feature virtually vibration-free carriage movement and offer a maximum stroke of up to 8.5 meters. Steel tension members reinforce the toothed belts made of different polyurethanes. The motor position at the end of the axis can be freely selected and can also be retrofitted.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.