Compact, precise and reliable

More and more samples have to be analysed in ever shorter time. The laboratories have been under pressure not only since March. Reliable and fast automation solutions from Festo are the answer.

At present, the test results for Covid-19 are eagerly awaited, the waiting time for the common PCR tests is currently up to one week. However, sample results are sometimes erroneous, the reason? The processes in laboratories are still mainly carried out manually by humans. Doubts about the correctness of the results make people feel uncomfortable. This is where reliable and fast automation solutions are required.

Highlights at COMAPMED 2020

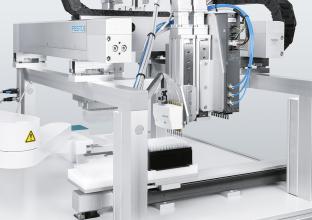

A highlight at this year's COMPAMED are ready-to-install solutions for in-vitro diagnostics in the field of Point of Care Testing (POCT). Compact analysis instruments make quick testing possible at the doctor’s office in order to identify the pathogen responsible for a cold or flu, as well as other bacterial or viral infections. In particular for this type of equipment, Festo offers ready-to-install automation solutions including customised engineering.

The compact rotary gripper module EHMD, which can grip and rotate sample vials, is unique on the market so far. It opens the smallest sample vials with a volume of up to 15 millilitres without any problems.

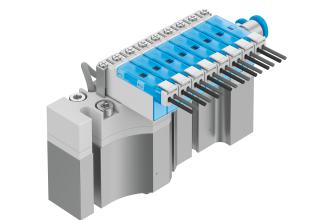

With the VYKA, a new media-separated solenoid valve for precise dispensing of liquids or control of liquid flows in manifold duct plates came onto the market. A current-controlled solenoid permits highly precise and reliable operation. Media separation ensures highest possible safety standards and chemical resistance. For higher flow rates the VYKB is used.

Components and subsystems for laboratory processes and medical devices

In addition to standard components, the LifeTech division develops separate components with new technologies that are designed specifically for laboratory processes and medical devices in Boston, a major hotspot of the life science market. When developing customised automation solutions for its customers, Festo follows the approach of working out engineering concepts together with the customer from the earliest planning phase onwards.

Product range for laboratory automation

Festo develops intelligent, tested subsystems for the automation of liquid media and sample handling applications.

The focus is on:

- Feeding and identification of test tubes

- Opening and closing of test tubes

- Feeding and aspiration of liquid media and solids

The applications involve the use of both electric and pneumatic actuators with motors, controllers, sample & liquid handling systems as well as grippers, sensors and camera systems.

Product range for medical technology

In the field of medical technology, Festo develops products and subsystems for medical devices.

The focus is on the efficient regulation and control of medical gases such as:

- Flow control with compact valves for ventilation and anaesthesia devices

- Pneumatic integration solutions for surgical devices

- Regulation of fluids in dental stations

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,800 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.81 billion in 2022. Each year around 7% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.