Festo increases turnover with electromobility

In 2020, Festo was able to increase sales in the "machines and systems for battery production" segment by 40 percent. The demand for automation for battery cell production and other e-vehicle components is increasing continuously.

The automotive industry is currently investing mainly in the development of new electric vehicles. Dr Ansgar Kriwet, Member of the Management Board for Sales: "In 2020, 70% of Festo's top projects in the automotive industry involved investments for electromobility." Based on this very good starting point, Festo expects significant double-digit percentage growth in the "Machines and systems for battery production" segment over the next few years.

Demand is increasing - opportunity for Festo

The degree of automation in production is increasing due to the electrification of powertrains. The traditional assembly of combustion engines involves the high-precision assembly of mechanical components, whereas the production of battery modules involves the assembly of very expensive and potentially dangerous electrochemical elements. In addition, there are new components compared to combustion vehicles: the electric motor, the batteries and the power electronics. Their production poses completely new challenges: For example, it is essential to avoid damaging the battery cells by dropping them. Festo therefore offers coordinated solutions for the robust, safe and precise gripping and transport of battery cells, particularly in the field of handling technology.

Key products

For battery production, copper-, zinc- and nickel-free automation components are necessary, such as the VTUG and VUVG valves in the "battery" version. Festo increases the productivity of its customers through engineering, for example with energy-efficient piezo valves VEAB and VEAE or with the servo press YJKP, which was sold in large numbers for battery cell production in order to press the wound batteries. In this case, the high quality pays off for the customers in battery production, because the batteries are very expensive and the plants run at a high cycle rate. Downtimes are costly and therefore prompt spare parts delivery and service are very important. In the last two years, Festo has invested in order to be able to cover all requirements for the portfolio. Festo's own research and participation in joint research projects, which focus on the handling process for the production of solid-state battery cells or the recycling of batteries, also contribute to their development.

Festo accompanies the entire process chain

Battery production is very complex. Festo offers industry-specific products and solutions for the manufacture of machines and systems along the entire process chain of battery cell production: From process automation products for raw material preparation to copper-, zinc- and nickel-free as well as dry- and clean-room compatible products for the fully automated production of battery cells to the assembly system for battery modules for installation in the vehicle. Festo also offers automation engineering and expert knowledge through to qualification by Festo Didactic and consulting by Festo Training and Consulting.

Unique combination: automation and training from a single source

Production facilities for components and electric vehicles are currently being built worldwide at short notice and at high speed. In order to train and on-board the large number of employees very quickly, who often do not have the right training or know-how, Festo Didactic offers industry-specific learning concepts: From access to the Festo Learning Experience Platform for self-study to learning factories for "hands-on" training with perfect knowledge transfer to the shop floor.

Safe battery handling

In a dynamic display Festo is presenting a modular assembly and disassembly system for battery modules and packs. The focus is on "safety" for safe handling of the battery modules. Mechanical fixings are placed underneath the cell with a swivel module to prevent unintentional loss of the cell. Parallel to the movement, an optical sensor system detects the mechanical alignment of the cell. In addition, its polarity is measured electrically. If the voltage is not correct, the cell is ejected. The cells checked in this way are inserted into the module housing in the appropriate orientation. If the battery is accidentally installed in the opposite direction to the intended polarity, this can lead to a short circuit of the module. A mechanical interlock on the cylinder secures the end position to prevent it from falling off in the event of an unforeseen loss of energy. Statistical process data monitoring evaluates data and indicates, among other things, when the gripper needs to be replaced. Festo thus uses a combination of pneumatic and electric drives, including sensors, in an energy-efficient manner.

Images and captions

Festo press image Electrification of Powertrain (Electromobility)

The demand for automation for battery cell production and other e-vehicle components is increasing. The degree of automation in production is increasing due to the electrification of powertrains.

(Photo: Festo SE & Co. KG)

Festo press image Electromobility symbol:

In 2020, Festo was able to increase sales in the "machines and systems for battery production" segment by 40 percent and sees great opportunities for further growth in this segment.

(Photo: Festo SE & Co. KG)

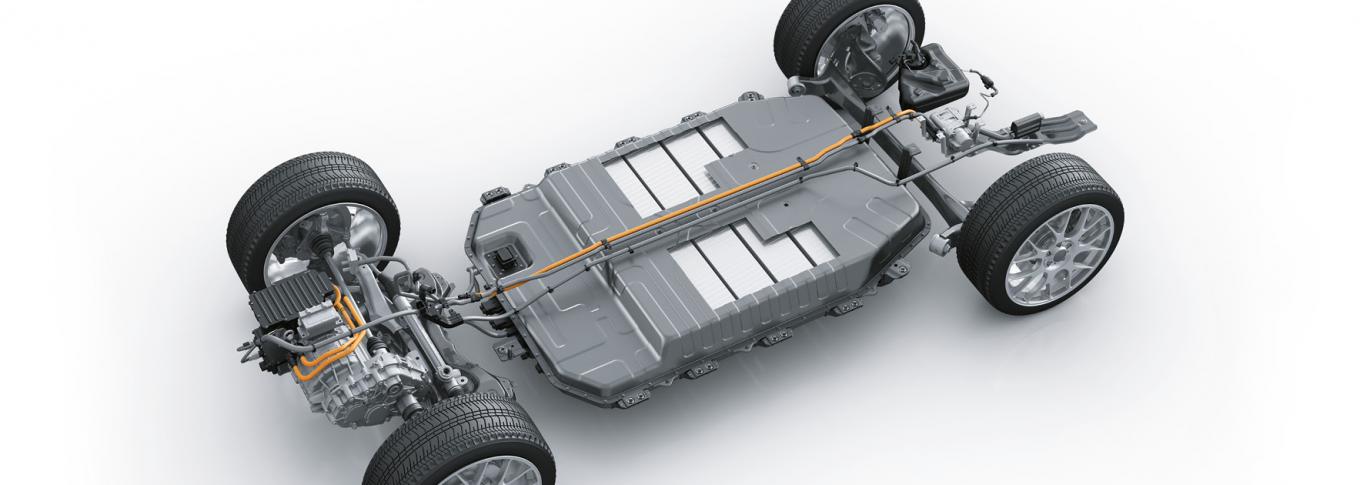

Festo press image Electrification of Powertrain real (Electromobility)

The demand for automation for battery cell production and other e-vehicle components is increasing. The degree of automation in production is increasing due to the electrification of powertrains.

(Photo: Festo SE & Co. KG)

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.