More performance, more speed, less energy

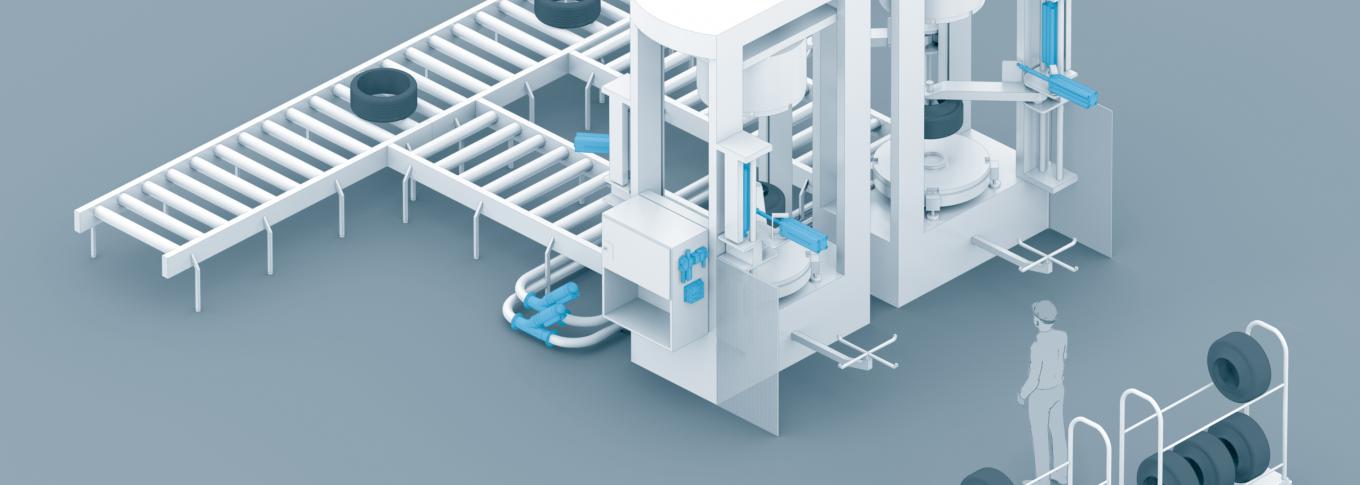

The Festo Motion Terminal VTEM, a product of the Industry 4.0 era, combines digitalisation and pneumatics. Quickly activated software apps are a game changer for pneumatics by increasing flexibility and energy efficiency, and accelerating production processes. This also benefits tire manufacturing, as demonstrated by the use of the automation platform VTEM in tire curing presses.

The Festo Motion Terminal VTEM is controlled via software apps that can replace over 50 individual components. Just as the smartphone turned the mobile communication market on its head a decade ago, so too is the Festo Motion Terminal set to change automation technology. The new type of function integration – combined with software apps – simplifies the entire value chain, since only one piece of hardware is now required.

Full flexibility

Thanks to the fast activation of new functions via apps, machine developers can create a basic machine type and then, depending on which apps are selected, equip it with different functions and features as per the customer’s requirements. Assigning functions via software has the added benefit of preventing tampering and protecting know-how, since it’s not possible to tell from the outside which functions the valves are executing. Maintenance is also simplified, as long lists of spare and wearing parts will be a thing of the past.

In tire manufacturing, this results in potential savings for loading operations at the curing presses, as the “selectable pressure level” app included with the Festo Motion Terminals ensures gentle loading of the green tire*. The smaller the fluctuations of the handling system during loading, the more the feeding-in speed can be increased. The process for each tire is thus accelerated by several seconds. This doesn’t sound like much at first, but with roughly 1.8 billion car tires produced each year, this can result in considerable sums for each tire manufacturer.

Less pressure = less energy

In practice, it is not just that the loading operations are accelerated, they also require less energy because pressure can be reduced and so compressed air consumption is also decreased. Calculations even reveal compressed air savings of nearly 33% when comparing the movement of the horizontally installed pneumatic cylinder DSBC with standard pneumatics, and of nearly 75% when the same cylinder is installed vertically. Just for controlling the vertical and horizontal cylinders, energy savings of roughly 60% are achieved for these loading and unloading operations.

Predictive maintenance

The “leakage management” app enables predictive maintenance by pinpointing leaks throughout the entire pneumatic control chain including valves, tubing, connectors and drives. The goal is to detect defective components at an early stage before they bring production to a standstill or damage the machine.

Furthermore, the Festo Motion Terminal can seal off the faulty air duct, thus preventing the supply of more and more compressed air in the case of a leak. The innovative automation platform thus prevents unnecessary air consumption.

New machines versus retrofitting

The Festo Motion Terminal makes retrofitting projects particularly easy, since the embedded functions can be assigned by software apps. Digitized pneumatics extends life cycles, improves the performance of machines and reduces energy consumption. It maximizes the spread of technology and thus multiplies the benefits from the tire manufacturer to the machine builder.

Smart maintenance as one brick in the “IoT wall”

Digitalization and artificial intelligence (AI) are mega trends that are also opening up the potential for savings in tire manufacturing. Machine learning algorithms can be implemented decentrally, e.g. – on edge, in other words at the specific production stage to be monitored. Decentralized monitoring of actuator characteristics, such as pressure in the actuator chambers, travel speeds and their variation over time, not only enables the parameters of the actuator itself to be analyzed, but also allows anomalies in the technical process to be detected.

This is the basis for predictive maintenance concepts and for data analyzes aimed at optimizing the production process. The artificial intelligence in the module controller detects any anomalies without the need for additional programming. The algorithms are taught in based on data representing normal production; they can then independently detect deviations in the production process or in the performance of the actuators. This enables plant operators to detect problems in good time and avoid unscheduled plant downtimes caused by malfunctions.

* In technical jargon, a green tire is the raw, unprofiled tire.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2023年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额36.5亿欧元。每年约7%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。