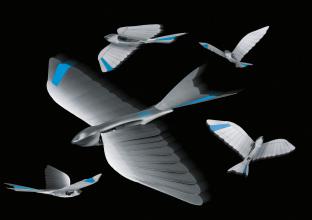

Artificial feathers give flight to robotic birds

Thanks to radio-based indoor GPS with ultra-wideband technology (UWB) the BionicSwifts can fly safely and in a coordinated pattern in a defined airspace. To execute these flight manoeuvres as true to life as possible, the wings are modelled on the plumage of real birds. The agility of the artificial birds is not just due to their lightweight design and aerodynamic kinematics, but also to the use of function integration.

The Festo Bionic Learning Network has a long tradition of being inspired by natural flight. The creation of the BionicSwift represents the next chapter for Festo in the development of bionic flying objects. As in its biological model, the use of lightweight structures is at the heart of the artificial bird. Because in both engineering and in nature, the less weight there is to move, the less material is required, and the less energy is consumed. That is why the BionicSwift weighs just 42 grams despite having a body length of 44.5 centimetres and a wingspan of 68 centimetres. This makes it extremely agile, nimble and capable of flying loops and making tight turns. By interacting with a radio-based indoor navigation system, the robotic birds are able to move autonomously in a coordinated pattern in a defined airspace.

Aerodynamic feathers

To be able to replicate natural flight as closely as possible, the wings of the BionicSwifts are modelled on bird feathers. The individual lamellae are made from an ultra-lightweight, flexible but very robust foam, and overlap each other. Connected to a carbon quill, they are attached to the actual hand and arm wings as in the natural model. The individual lamellae fan out during the wing upstroke, allowing air to flow through the wing. This means the birds require less power to propel the wing upwards. The lamellae then close during the downstroke to provide the flying robot with a more powerful flight. This close replication of bird wings gives the BionicSwift a better flight profile than previous beating wing drives.

Function integration in the tightest of spaces

The agility of the artificial bird is not just due to its lightweight design and aerodynamic kinematics, but also to the use of function integration. The bird’s body contains the compact construction for the wingflapping mechanism, the communication technology, the control components for wing flapping and the elevator, the tail. A brushless motor, two servo motors, the battery, the gear unit and various circuit boards are installed in the smallest of spaces. Through the intelligent interaction of the motors and mechanical systems, the frequency of the wing beats and the elevator for the various manoeuvres can be precisely adjusted.

GPS coordination of the flight manoeuvre

The coordinated and safe flight of the robotic birds is made possible by radio-based indoor GPS with ultra-wideband technology (UWB). Several radio modules are mounted in the space, forming fixed anchors that locate each other and define the controlled airspace. Each bird is equipped with a radio marker that sends signals to the bases, which can then locate the bird’s exact position and send the data collected to a central master computer, which functions as a navigation system. The system can use preprogrammed paths to plan and determine routes and flight paths for the birds. If the birds deviate from this flight path, for example due to a sudden change in ambient conditions such as wind or thermals, they immediate correct their flight path by intervening autonomously – without any human pilots. Radio-based communication means that position sensing is possible, even if there are obstacles and visual contact is partially lost. The use of UWB as radio technology guarantees safe and interference-free operation.

New inspiration for intralogistics

The intelligent networking of flight objects and GPS routing makes a 3D navigation system that could be used in the networked factory of the future. For example, by precisely locating the flow of materials and goods, process workflows can be improved and bottlenecks can be predicted. In addition, autonomous flying robots could be used for transporting materials, with their flight corridors a way of optimising the use of space within a factory.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。