Control several flow rates simultaneously

The Festo Motion Terminal VTEM combines digitalisation and pneumatics. Quickly activated Motion Apps are revolutionising pneumatics by increasing flexibility and energy efficiency, and accelerating production processes. Thanks to the new Motion App “Flow control”, the VTEM now makes filling containers such as bottles with nitrogen or other gases more profitable and economical.

Digitised pneumatics marks the start of a new age of automation technology. Motion Apps control one piezo valve for almost all pneumatic tasks. Only one piece of hardware is needed for this: the Festo Motion Terminal. The different functions are controlled using Motion Apps. Festo is gradually developing new Motion Apps that are making the Festo Motion Terminal more and more flexible. This reduces complexity and time to market. Digitised pneumatics intelligently connects the mechanical system, electronics and software, and ensures better overall equipment effectiveness (OEE) with lower energy consumption.

Digitised flow control

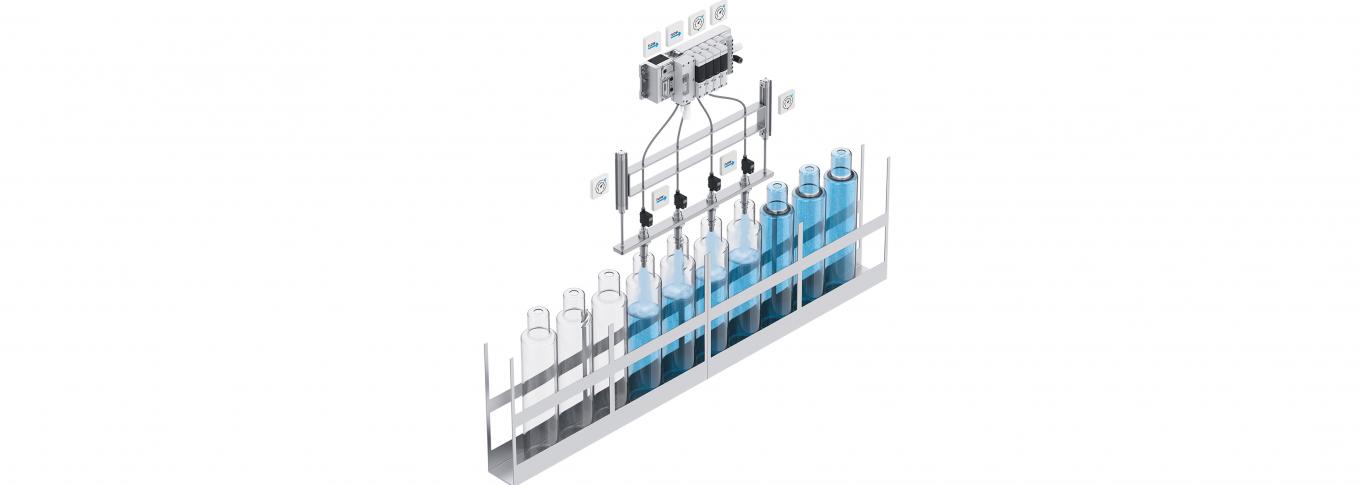

An application example: nowadays containers for products are often rinsed and filled with gases like nitrogen. With the Motion App “Flow control”, users control the flow rate of compressed air and gases at up to 600 l/min digitally – simultaneously on up to eight independent channels. For precise dosing, the integrated sensors can simply be combined with external flow sensors. This saves energy and costly gases.

Controlling the flow in litres per minute using the app allows the gas to be precisely dosed. The more precisely the filling quantity is defined, the more accurate the filling will be since the percentage deviation from the target quantity can be optimally detected. This flexible, digitised nitrogen control is tamper-proof.

In addition, the app “Selectable pressure level” moves the filling nozzles to the bottles quickly and accurately, and the flexible parameterisation shortens the cycle times. After filling, the filling nozzles are retracted with reduced pressure to save energy.

Software instead of hardware

Thanks to the fast activation of new functions via Motion Apps, machine developers can create a basic machine type using the Festo Motion Terminal and then select the relevant Motion Apps to equip it with different functions and features as per the customer requirements. The ability to copy and transfer parameter sets makes planning easier and saves time. Assigning functions via software has the added benefit of preventing tampering and protecting know-how, since it’s not possible to tell from the outside which functions the valves are executing.

By additionally using the Motion App “Leakage diagnostics” in the application, maintenance is simplified as it automatically monitors for leaks. Malfunctions can thus be detected and pinpointed to a specific actuator using diagnostic cycles and defined threshold values – the reliable basis for predictive maintenance.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。