Optimising curing presses with AI

Digitalisation and artificial intelligence (AI) are megatrends that can also offer great potential for savings in tyre production. Machine learning algorithms can be implemented in a decentralised manner, for example on the edge, i.e. on the actual module to be monitored. An example is Festo AX. This AI software uses these algorithms to detect anomalies on tyre building machines or in curing presses.

Decentralised monitoring of the properties of an actuator used in the curing press, such as pressure, movement speeds and their development over time, not only enables the parameters of the actuator itself to be analysed, but also the detection of anomalies in the entire process. This is the basis for predictive maintenance concepts and for data analyses to optimise the production process. The artificial intelligence in the module control detects anomalies without additional programming effort.

Recognising problems in good time

The algorithms are taught using data from normal production and can then independently detect deviations in the production process or in the performance of the actuators. This enables plant operators to detect problems in good time and avoid unplanned plant shutdowns due to malfunctions.

In order to increase the plant availability (OEE) of a heating press, analyses showed that the generation of steam accounts for the lion's share of energy consumption and that the process valves for controlling the steam are subject to great wear. These circumstances need to be addressed, because the wear of the sealing material on the process valves means that they need to be replaced every 18-24 months in the curing presses. If a tyre factory has 200 curing presses in use, about 1500 process valves are installed. The average cost is 300 €. Extrapolated to 18-24 months, this results in costs of 450,000 €.

Avoid machine downtimes

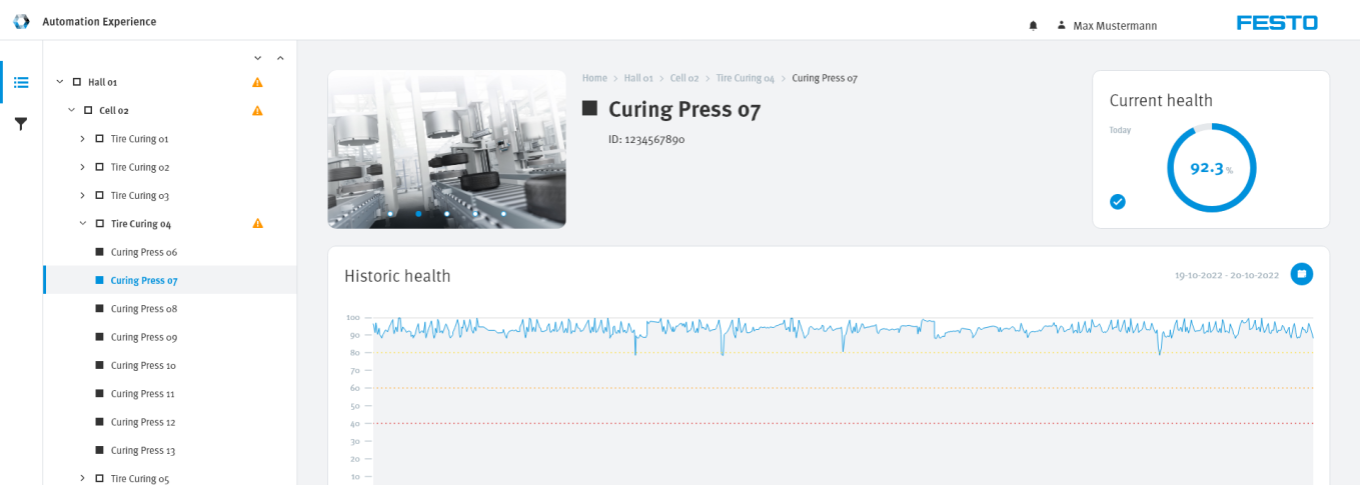

Digitalisation solutions with artificial intelligence can detect faults before they lead to the sudden breakdown of a component. This enables maintenance staff to intervene in good time to avoid machine downtimes. One of these software solutions is the Festo Automation Experience, or Festo AX for short: "It increases the performance of machines and systems, making customers even more successful," explains Dr Oliver Niese, Head of Digital Business at Festo.

In addition to its know-how in automation technology, Festo also has domain expertise. With the acquisition of the software company Resolto, the company also has access to expertise in advanced analytics and artificial intelligence. The combination of these three parts results in the Festo AX software solution.

"Festo AX helps our customers to make decisions based on facts," emphasises digitalisation expert Niese. Festo Automation Experience (Festo AX) is an easy-to-use solution that enables users to extract maximum value from their plant data through artificial intelligence (AI) and machine learning.

Analyse data and increase productivity

Simply by analysing data with Festo AX, users can increase productivity, reduce energy costs, avoid quality losses, optimise the shop floor and create new business models. "With the Predictive Maintenance, Predictive Energy and Predictive Quality modules, we work with our customers to implement their individual solutions,” explains Niese.

Festo AX offers artificial intelligence in real time. It can be flexibly integrated into the customer's system - on premises, on edge or in the cloud. The user himself remains the owner of the collected data and no one else. Data analysis is not limited to components and modules from Festo itself. "A major advantage on the market is that our software also makes it possible to reliably analyse components from other manufacturers," emphasises digitalisation expert Niese.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.