Cycle times reduced by 30 per cent

Compact design for 30% shorter cycle times and 50% less vibration – those are the most important characteristics of the cantilever axis with toothed belt ELCC-TB from Festo. The axis fits in seamlessly with Festo's concept of complete connectivity for its electric automation technology.

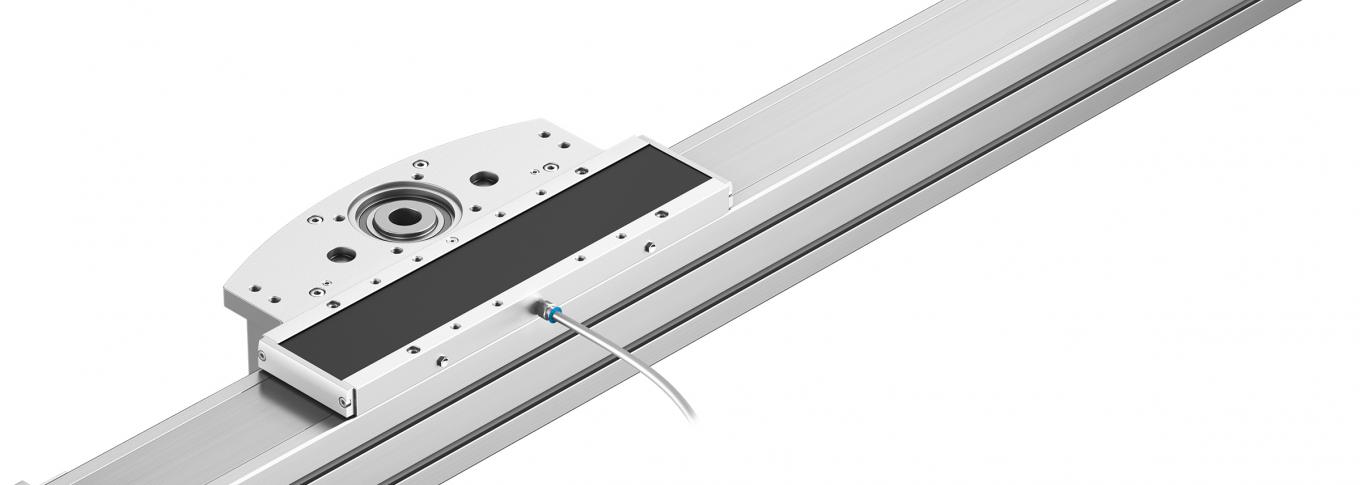

The high rigidity of the toothed belt cantilever axis cuts vibrations in half, whilst the low moving mass of the compact design reduces cycle times by almost a third. A stainless steel cover strip protects the internal recirculating ball bearing guide. Thanks to sealing air, the cantilever axis ELCC-TB is suitable for use in dusty environments or on machine tools. A clamping unit securely holds loads and acts as an emergency brake.

With a stroke of up to two metres, the cantilever axis is ideally installed vertically as a Z-axis, for example for palletising or erecting boxes. It can also be used horizontally or at any other installation angle if the axis has to be removed from the working space.

Complete connectivity

The cantilever axis ELCC-TC is an important part of Festo's philosophy of complete connectivity, i.e., the ability to connect a workpiece completely through to the cloud, from its mechanical connections and electrical interfaces to commissioning and controller programming. This simplifies the work of every machine builder and automation engineer when it comes to connecting the mechanical and electric technology as well as the control levels and their interfaces with the hardware and software.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.