Automating depowdering in 3D printing

Industry experts are forecasting a golden era for additive manufacturing, with annual growth rates of 24% anticipated into 2024. The automation of 3D printing processes offers further growth potential, for example in feeding or depowdering the components. When it comes to the depowdering of laser-melted metal parts, Solukon is the world's leading supplier. It is working together with Festo, the global player in industrial automation technology, to establish whether it is possible to push the level of automation for depowdering even further and, if so, by how much.

Solukon's powder removal systems are already considered to have the leading technological edge. Based on Solukon’s proprietary Smart Powder Recuperation technology (SPR®), these cleaning systems remove the powder residues from complex 3D-printed metal components through an automated process of swivelling and vibration excitation. With the advanced frequency system, the flow of the powder can be continually controlled so that narrow openings and channels can be depowdered.

Thanks to this technology, Solukon machines can also depowder components with complex voids and channels such as heat exchangers. The Solukon systems already offer three benefits compared with the conventional manual cleaning of components: reproducibility, cost reduction and safety. The automated process for swivelling and vibrating the components can be standardised and is reproducible.

Blowing off powder using compressed air

Automated depowdering processes can sometimes struggle to remove powder from component surfaces despite rotating and vibrating the component, particularly when dealing with difficult-to-handle materials like copper. Using a light and direct blow of air will dislodge these fine deposits. By blowing air through the channels it is also possible to check that they are free of deposits. Currently this is a manual procedure that can be carried out easily at the Solukon system using glove ports. However, larger components with a height of at least 1 metre make access more difficult and this requires automated support. A joint project between Festo and Solukon to investigate handling solutions and kinematics will show how this process can be designed with maximum efficiency.

Increasing complexity

One trend that is becoming clear in additive manufacturing is that components are increasing in size and in the complexity of their inner geometries. Solukon’s aerospace customers have particularly high requirements. It is also a sector where the demand for large components manufactured using additive methods is steadily growing. However, these large components are more complex to handle than small components with simple geometries.

The aim of the joint research project is to optimise existing automated processes for depowdering. A fully automated and integrated process chain would also be possible. Overall, the manufacturing costs for the components would go down.

Automated handling system

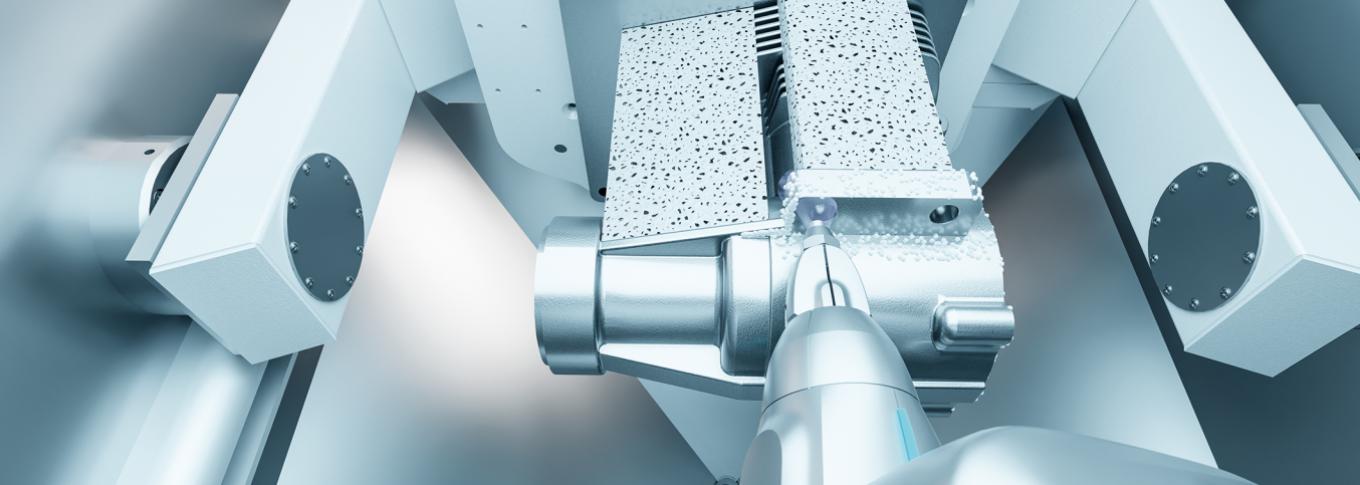

The project involves adding a handling system to the depowdering system. This system automatically moves the blowing or machining tool. The challenges for this automation solution lie in the flexible adaptation of the motion profile to changing component contours and in the ambient conditions, where the key issues are dust protection, ATEX and protected atmosphere.

Festo and Solukon are currently working on a concept to simulate the automation platform that provides the necessary, flexible machining possibilities. This includes a feasibility analysis of how accessible the working space is. In a visionary move, artificial intelligence could support contour detection using the CAD data of the component to be machined. “We are delighted to be partnering with Festo, and to have its innovative strength and expertise in automation technology on board for this project”, says Andreas Hartmann, CEO and technical director of Solukon Maschinenbau GmbH.

Taking full advantage of the potential of automation

Fully automated and residue-free depowdering should lead to accelerated, precise and reproducible processes and ensure that manual rework is no longer necessary. This will significantly cut the manufacturing costs for different batch sizes. “Up to now, we have not taken advantage of the potential of automation in many process steps. We therefore see these innovative automation approaches as great opportunities for the future topic of additive manufacturing”, explains Felix Hantsch, project manager in Innovation and Robotics Cluster DACH at Festo.

In an animation, the project partners Festo and Solukon visualise the potential of their project for the optimisation of fully automated depowdering processes:

https://www.youtube.com/watch?v=HMkdPd5iKjM

About Solukon:

Solukon Maschinenbau is an international, state-of-the art, international, owner-operated company that specialises in the development, assembly and sale of cleaning booths for industrial 3D printing. Established in 2015 by Andreas Hartmann and Dominik Schmid, the company which is located in Augsburg, Germany, has extensive experience in the development of additive manufacturing systems and the associated peripherals and offers a wide range of individual powder processing systems. Solukon products meet the highest standards in terms of functionality and safety, and are approved as a safe and reliable way of removing difficult-to-handle and reactive materials like titanium and aluminium. Leading manufacturers of 3D printing systems including AMCM, SLM-Solutions and EOS, institutes like NASA and CERN, and companies like Siemens and the ArianeGroup rely on Solukon systems.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。