Eichenberger convinces compared to products from the Chinese market

Eichenberger successfully held its own against local Chinese manufacturers in the planning of the new Festo gripper due to outstanding quality (5000% more operational performance in the endurance test), production from a single source, years of expertise and close cooperation throughout the development process from start to finish.

„The threaded spindles from Switzerland really impressed Festo and helped the company to develop a competitive, high-performance electric parallel gripper within a very short time,“ says Dr Ralf Hartramph, Business Development Manager at Festo and former Head of Development of the Festo Technical Engineering Center in Shanghai.

New parallel gripper in shortest time

After a product range was discontinued and consequently, compatibility with the existing gripper was lost, Festo urgently needed a replacement. Therefore, Festo TEC Shanghai developed a new parallel gripper in the shortest possible time, with low manufacturing costs as an additional benefit.

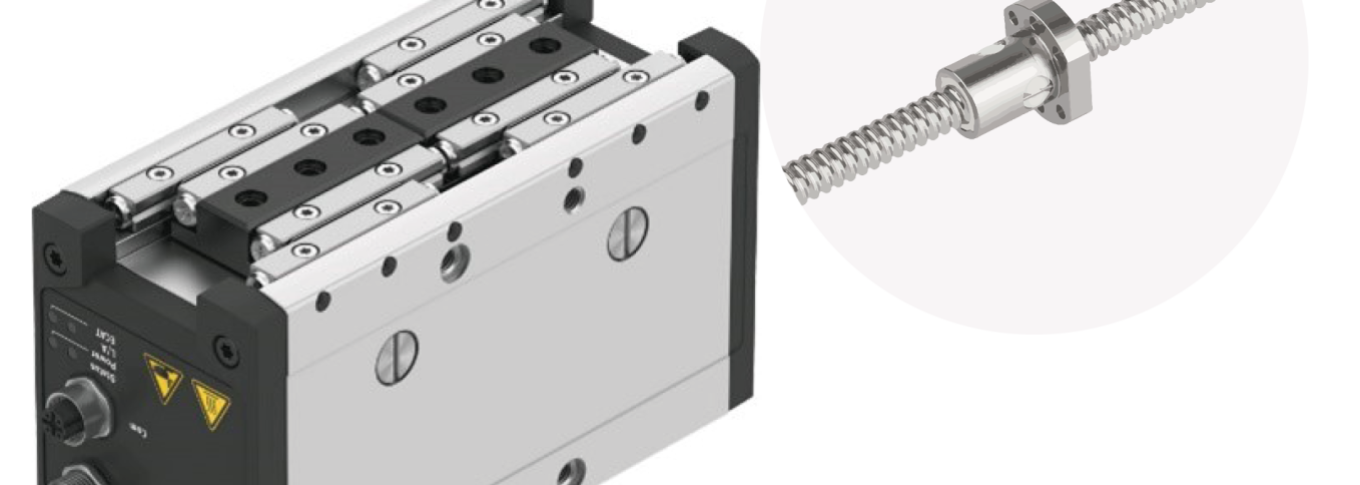

In the main, the HEPP gripper was developed locally in China, where the components were sourced and manufactured. One exception was the screw drives, as these are subject to high quality standards. Only the Swiss company Eichenberger Gewinde was able to meet these requirements, and not one of the local manufacturers reached the standard.

5000% more runninge performance

„The counter-rotating spindles in the HEPP gripper from Festo are subjected to considerable stress by the feeder forces. To our surprise, the first lifetime test showed very significant differences between Eichenberger and all other spindle suppliers: the Eichenberger spindles showed almost 5000% more running performance. Not only did this convince us, but this also adds considerable value to our product,“ Hartramph explains.

The close cooperation between the development teams right from the start was another success in the rapid implementation of the project: together, Eichenberger and Festo in Shanghai developed the customised counter-rotating ball screws, so that within a few weeks the first sample screws were ready for lifetime endurance testing, which accelerated the development process enormously.

Cross-location teams

Furthermore, using multifunctional and cross-location teams together with the internally developed mechatronics, a competitive product that can withstand the most demanding requirements was created. As a result, the HEPP gripper is the first completely in-house developed electric parallel gripper from Festo, designed to be more profitable and also more compact than previous models. Festo has excelled in this respect and we are proud that our lead screws form part of this outstanding product, which is used in the automotive and electrical automation industries, among others.

费斯托 (Festo)是一家全球性的独立的家族企业,总部位于德国埃斯林根。自成立以来,Festo在工业自动化技术和技术教育方面制定标准,从而为环境、经济和社会的可持续发展做出贡献。公司为超过35个行业的30万家工厂和过程自动化客户提供气动和电驱动自动化技术解决方案,其中生命科学和实验室自动化业务受到越来越多的关注。Festo产品和服务遍布176个国家。2024年,费斯托在全球61个国家的250多个分支机构拥有约20600名员工,实现销售额34.5亿欧元。每年约8%的销售额用于研发。在这家学习型企业,1.5%的销售额用于基础和进一步培训。Festo 教学培训 (Didactic SE) 是全球领先的技术教育和培训供应商,为全球客户提供工业环境中全面的数字化和常规学习解决方案。